Description:

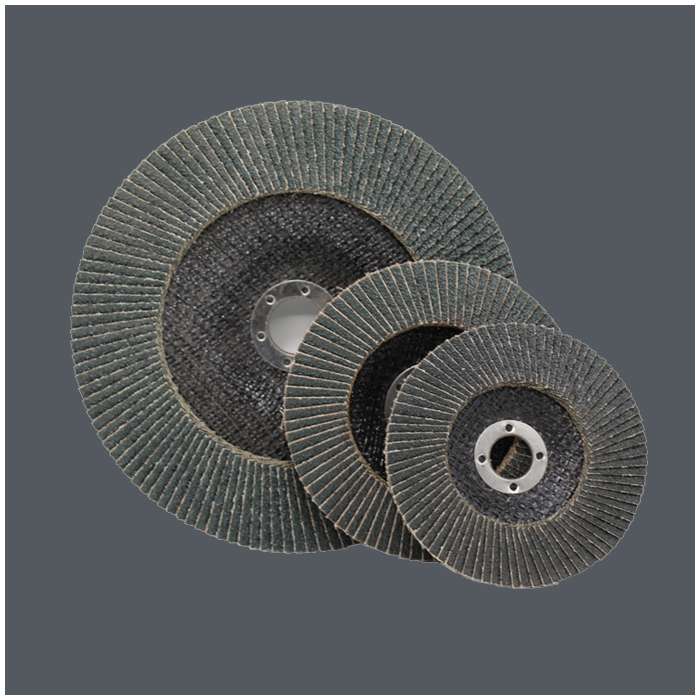

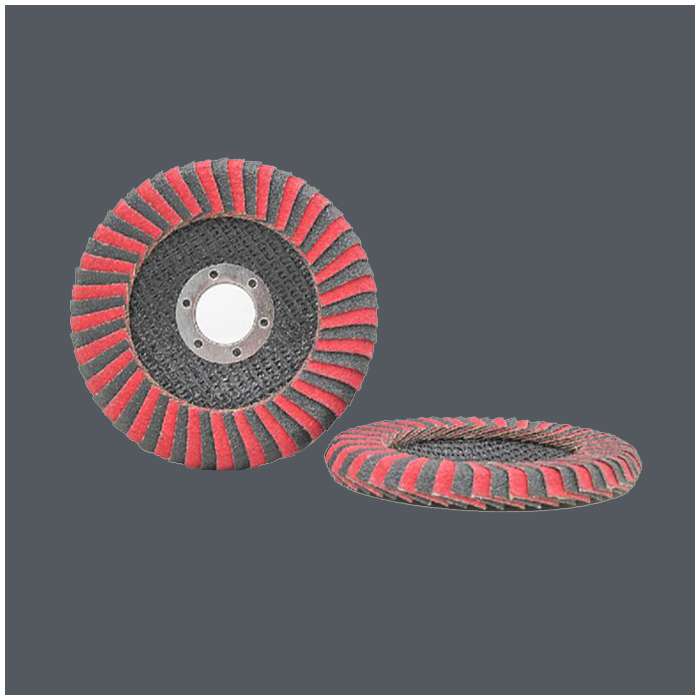

- Zirconia oxide flap discs are high-efficiency grinding tools made by combining zirconia (ZrO2) abrasive grains with a flexible base material. These flap discs are widely used for surface treatment of various materials, including metals, woods, and plastics, due to their excellent durability and adaptability.

Feature:

- High Durability: Zirconia abrasive grains are known for their high hardness and superior wear resistance, ensuring the flap discs remain sharp during extended use.

- Cool Grinding Characteristics: They generate less heat during the grinding process, reducing the risk of thermal damage to the workpiece.

- Material Adaptability: Suitable for grinding a variety of materials, including stainless steel, alloy steel, aluminum, wood, and plastics.

- Flexibility: The flexibility of the base material allows the flap discs to conform to the workpiece surface, achieving uniform grinding.

Specification:

Diam X Bore(mm) | Grit Available | TYPE | Max.RPM(r/min) | Packing ( units/pcs) | |

T27 | T29 | ||||

100 X 15 | P36/40/60/80/100/120 |

|

| 15300 | 10 |

| 100 X 16 | P36/40/60/80/100/120 | 15300 | 10 | ||

115 X 22 | P36/40/60/80/100/120 | 13300 | 10 | ||

| 125 X 22 | P36/40/60/80/100/120 | 12200 | 10 | ||

150 X 22 | P36/40/60/80/100/120 | 10200 | 10 | ||

| 180 X 22 | P36/40/60/80/100/120 | 8500 | 10 | ||

230 X 22 | P36/40/60/80/100/120 | 6600 | 10 | ||

| 250 X 22 | P36/40/60/80/100/120 | 6000 | 10 | ||

Application:

- Metalworking: Used for grinding, deburring, and polishing metal surfaces.

- Woodworking: Used for sanding and smoothing wood surfaces.

- Plastic Processing: Used for trimming and surface treatment of plastic parts.

- The zirconia flap discs are utilized for stock removal, edge grinding, seam weld blending, de-burring and surface finishing. They can be used on chromium steels, CrNi steels, high alloyed steel, cat iron, nickel-based alloys, titanium alloys, non-ferrous metals and even high carbide steels.

Usage and Maintenance:

- Proper Installation: Ensure that the flap discs are correctly mounted on the grinding equipment, following the manufacturer’s guidance.

- Speed Matching: Operate according to the recommended working speed of the flap discs to ensure optimal grinding results and disc life.

- Regular Inspection: Regularly inspect the wear of the flap discs and replace them promptly if severely worn to ensure grinding quality.

- Storage Conditions: Store away from moisture and extreme temperatures to prevent a decline in abrasive performance.

Safety Notes:

- Read the product manual and safety operating procedures carefully before use.

- Wear appropriate personal protective equipment when operating, such as safety goggles, dust masks, and gloves.

- Ensure good ventilation in the workplace to reduce the inhalation of dust and grinding particles.

Zirconia oxide flap discs are an efficient tool for industrial grinding operations, suitable for grinding and polishing various materials. Correct use and maintenance can maximize the performance and service life of the flap discs.

More about :

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.