| Smelting Process | Produced by melting bauxite, iron filings, and anthracite at high temperatures in an electric arc furnace. | Obtained by calcining aluminum oxide at high temperatures, a process that yields a finely uniform crystalline structure, resulting in its white appearance. |

|---|

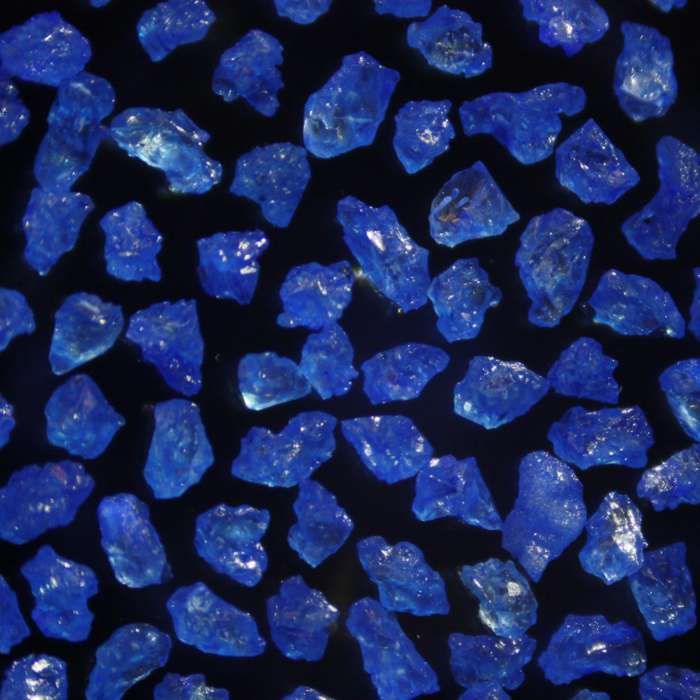

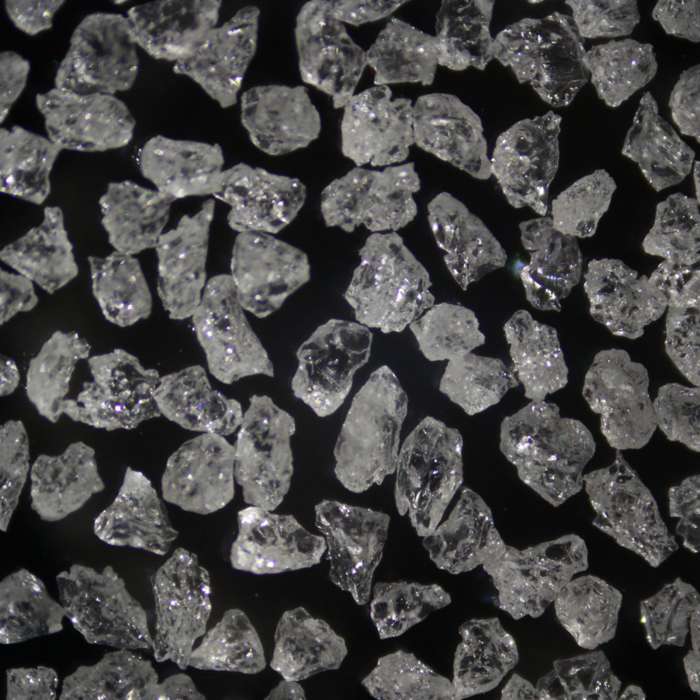

| Color and Crystal Structure | Typically brown in color, this is due to the presence of a small amount of iron elements. Its crystal structure is relatively coarse, containing prism-shaped crystals and brown particles, which endow Brown Fused Alumina with high abrasion resistance. | White in color, its crystal structure is relatively fine and uniform, manifested as hexagonal columnar crystals. This gives White Fused Alumina higher hardness and excellent wear resistance. |

|---|

| Hardness and Performance | Exhibiting relatively high hardness and wear resistance, it is suitable for general grinding and cutting applications. Its microcrystalline structure also imparts high toughness, aiding in resistance to mechanical impacts. | Possessing higher hardness, it is widely used in the preparation of superhard materials and in high-precision grinding. Its particle structure also makes it suitable for applications requiring strict surface smoothness. |

|---|

| Application | Mainly used in general grinding, polishing, sandblasting, etc. Its wear resistance and toughness make it perform exceptionally in processing metals, ceramics, glass, and other materials. | - Extensively utilized in applications demanding high hardness, precision, and smooth surfaces such as grinding, cutting, polishing, and abrasive coatings. It is also used in the production of high-hardness ceramics and electronic components.

|

|---|

Reviews

There are no reviews yet.