Description:

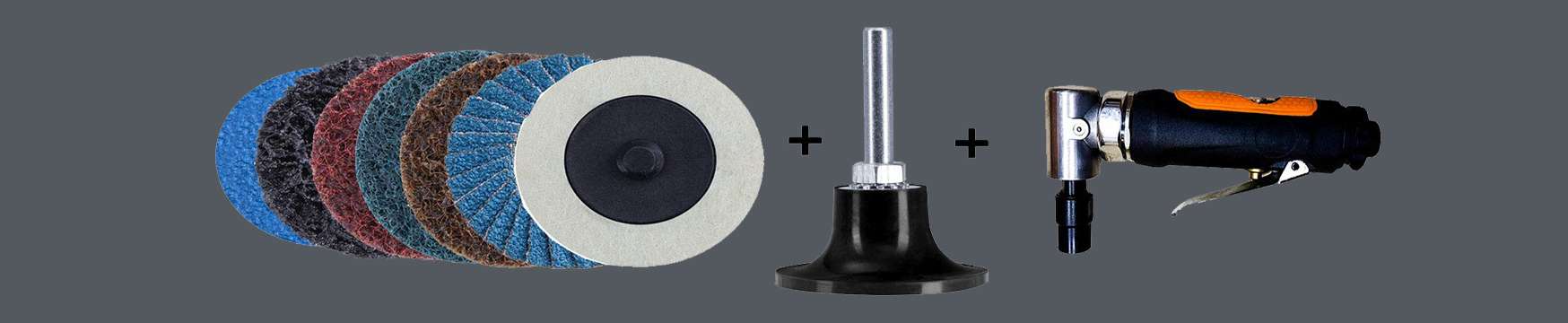

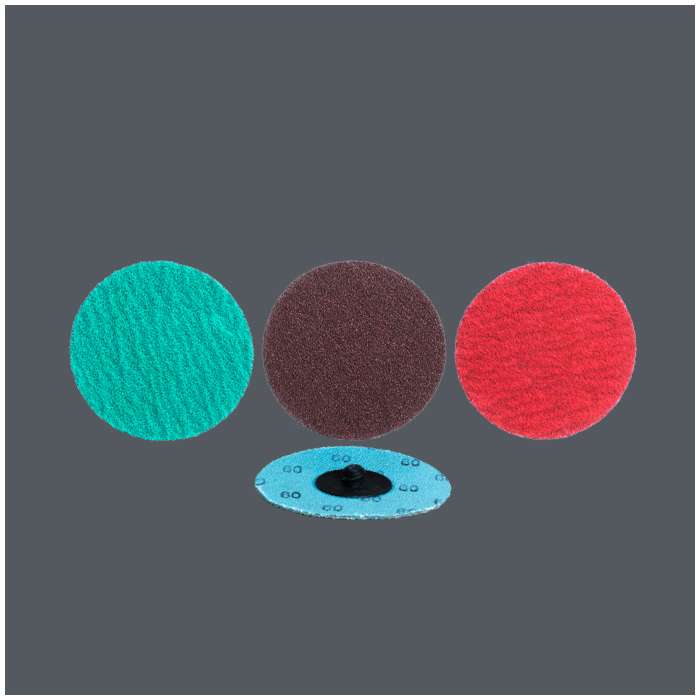

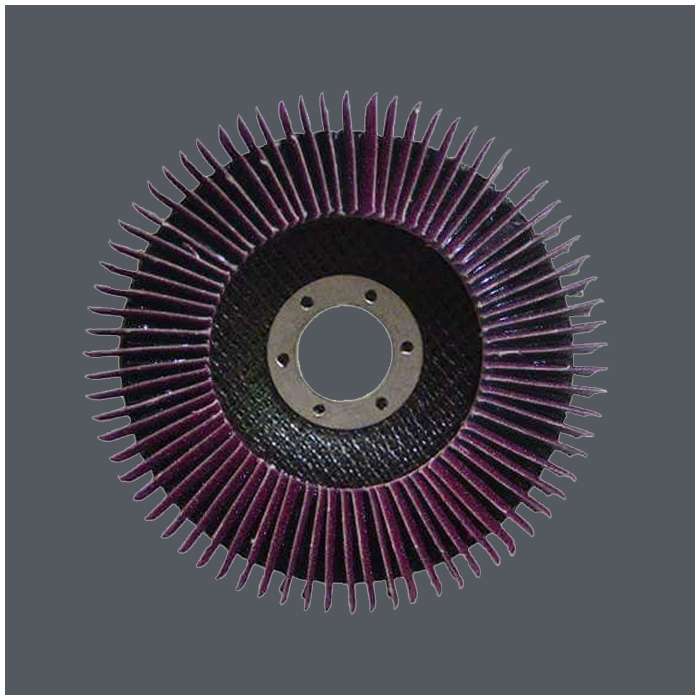

- Quick Change Disc, also known as fast change discs, are designed for efficient grinding with a quick change mechanism for the abrasive material. These discs typically feature a special clamping system that allows for easy and tool-less replacement of worn abrasives, enhancing work efficiency and reducing downtime.

Feature:

- Quick Change: The disc is designed with a quick-release mechanism that facilitates the swift replacement of worn abrasives by the user.

- High Efficiency: The quick change design minimizes the time required for changing abrasives, increasing production efficiency.

- Good Compatibility: Suitable for a variety of grinding equipment, including angle grinders and polishers.

- Durability: The robust structure and use of wear-resistant materials ensure the longevity and stability of the disc.

- Alumina, Zirconia, Ceramic Alumina and Silicon carbide series of quick change discs can provide excellent efficiency with their rapid tool change and ease of use. They prevent heat build-up during operation and they are built to be vibration free for outstanding operation. The quick change discs are ideal for tool and mold-making and other jobs that require fine detail work.

Specifications:

Diam X Bore(mm) | Grit Available | Max.RPM(r/min) | Packing ( units/pcs) |

| 25 | P24/36/40/60/80/120/150/180/240/320 | 30000 | 200 |

40 | P24/36/40/60/80/120/150/180/240/320 | 30000 | 100 |

50 | P24/36/40/60/80/120/150/180/240/320 | 22000 | 100 |

| 75 | P24/36/40/60/80/120/150/180/240/320 | 20000 | 50 |

Application:

- Metalworking: Used for grinding, deburring, and polishing metal surfaces.

- Automotive Repair: Used for quick repair and surface treatment of automotive parts.

- Construction Industry: Used for grinding and finishing building materials such as stone and concrete.

- Quick Change Disc can be used for general purpose grinding in a wide variety of applications from aggressive stock removal and coarse grinding all the way to surface finishing and polishing for a variety of metals, plastics, wood, paint and coatings.

Usage and Maintenance:

- Proper Installation: Following the manufacturer’s guidance,the grinding equipment correctly mounted the disc.

- Speed Matching: Operate according to the recommended working speed of the disc to ensure optimal grinding results and disc life.

- Regular Inspection: Regularly inspect the wear of the disc and replace it promptly if severely worn to ensure grinding quality.

- Storage Conditions: Store away from moisture and extreme temperatures to prevent a decline in abrasive performance.

Safety Notes:

- Read the product manual and safety operating procedures carefully before use.

- Wear appropriate personal protective equipment when operating, such as safety goggles, dust masks, and gloves.

- Ensure good ventilation in the workplace to reduce the inhalation of dust and grinding particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.