Description:

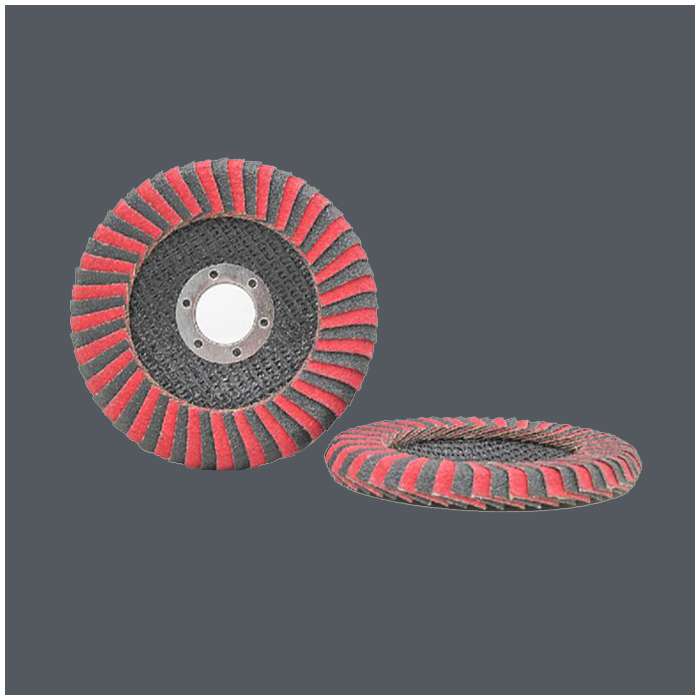

- Mounted Flap Wheels, also known as bonded flap wheels, are abrasive tools designed for a wide range of grinding, polishing, and finishing applications.

- Mounted Flap wheels are mounted on a backing plate or hub, which allows for easy attachment to an angle grinder or other rotary power tools. The mounted design ensures stability and precision during operation.

- Material: Aluminum oxide cloth, zirconia cloth or silicon oxide cloth.

- Shrank: 3mm/ 6mm / 6.35mm.

Features:

- Convenience: Ready to use out of the box, mounted flap wheels eliminate the need for additional mounting procedures.

- Versatility:

- Capable of accommodating a range of materials—including metal, wood, and plastic—the suitability is contingent upon the specific abrasive material and grit size selected for the task.

- Efficient Material Removal: The flap design allows for rapid material removal and prevents loading, making them ideal for heavy-duty grinding.

- Uniform Finishing: Provides a consistent and even surface finish across the workpiece.

Specifications:

| Dimensions (mm) | Dimensions (inches) | Grit Available | Max. RPM | Packaging | |||||||||

| Diam. x Thickness x Shank | Diam. x Thickness x Shank | units/pcs | |||||||||||

| 20 | x | 10 | x | 6.35-20 | 3/4 | x | 3/8 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 30,000 | 10 | |

| 20 | x | 20 | x | 6.35-20 | 3/4 | x | 3/4 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 30,000 | 10 | |

| 25 | x | 25 | x | 6.35-20 | 1 | x | 1 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 30,000 | 10 | |

| 30 | x | 20 | x | 6.35-20 | 1-3/16 | x | 3/4 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 30,000 | 10 | |

| 30 | x | 25 | x | 6.35-20 | 1-3/16 | x | 1 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 30,000 | 10 | |

| 30 | x | 30 | x | 6.35-20 | 1-3/16. | x | 1-3/16 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 30,000 | 10 | |

| 40 | x | 15 | x | 6.35-20 | 1-5/8 | x | 5/8 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 25,000 | 10 | |

| 40 | x | 20 | x | 6.35-20 | 1-5/8 | x | 3/4 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 25,000 | 10 | |

| 40 | x | 25 | x | 6.35-20 | 1-5/8 | x | 1 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 25,000 | 10 | |

| 40 | x | 30 | x | 6.35-20 | 1-5/8 | x | 1-3/16 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 25,000 | 10 | |

| 50 | x | 25 | x | 6.35-20 | 2 | x | 1 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 25,000 | 10 | |

| 50 | x | 30 | x | 6.35-20 | 2 | x | 1-3/16 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 25,000 | 10 | |

| 60 | x | 20 | x | 6.35-20 | 2-1/2 | x | 3/4 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 20,000 | 10 | |

| 60 | x | 25 | x | 6.35-20 | 2-1/2 | x | 1 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 20,000 | 10 | |

| 60 | x | 30 | x | 6.35-20 | 2-1/2 | x | 1-3/16 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 20,000 | 10 | |

| 76 | x | 25 | x | 6.35-20 | 3 | x | 1 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 20,000 | 10 | |

| 76 | x | 50 | x | 6.35-20 | 3 | x | 2 | x | 1/4″-20 | P40/P60/P80/P120/P150/P180/P240/P320 | 20,000 | 10 | |

Application:

- Metalworking: For deburring, grinding, and polishing metal surfaces.

- Woodworking: For sanding and smoothing wood surfaces.

- Automotive: For polishing and finishing automotive parts and bodywork.

- Construction: For grinding and smoothing concrete, masonry, and other construction materials.

- Work Surfaces: Stainless steel, standard steel, alloyed steel, aluminum, nonferrous materials and alloys, plastic materials, glass fiber, rubber, marble, stone, concrete, wood, hide or leather.

Usage and Maintenance:

- Proper Fitment: Ensure the wheel is securely attached to the power tool according to the manufacturer’s instructions.

- Speed Compatibility: Operate the flap wheel at the recommended speed to prevent damage and ensure optimal performance.

- Regular Inspection: After each use, thoroughly inspect the wheel for any signs of wear and damage, and replace it promptly if necessary.

- Storage Conditions: Store in a cool, dry place away from direct sunlight to maintain the integrity of the adhesive and abrasive material.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, when operating flap wheels.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.