Description:

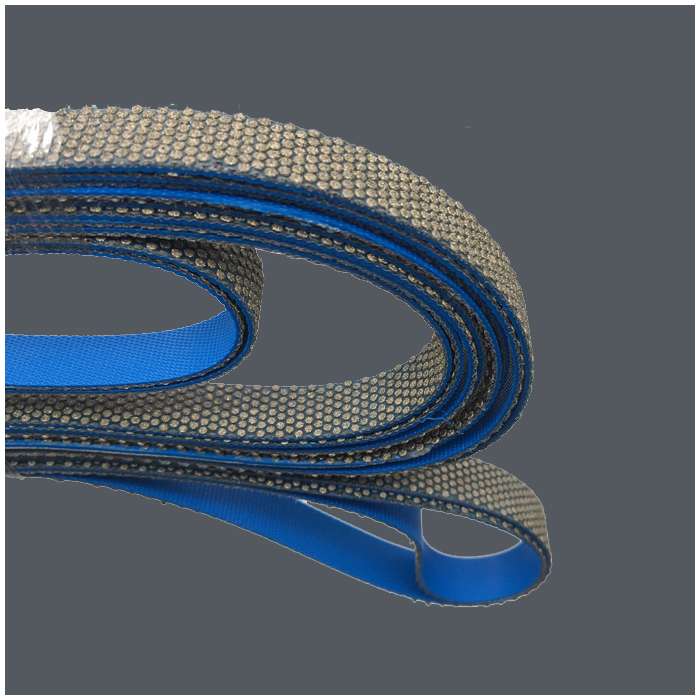

The specific description of the Diamond saw blade is as follows:

-

High Quality Diamond: We use high strength and dorin angle diamond for the segment, the blade will more sharp and more longer cutting.

-

High Quality Steel Blade: Most of the steel blade use 65Mn steel, this material easy deformation and low welding performance, these defects let the blade life is short. But our blade use 50Mn2V steel, this material contain 0.08%-0.16% vanadium, it lets the quenched performance more better, it also increase more manganese and reduce the carbon, all the advantage can let the blade more strength and more long cutting.

-

Thin and Fast Diamond Cutter: Our diamond cutter is thin from 0.5mm to 2.0mm, this can offer fast cutting and save the material of the cutting part, also the kerf of the processing part not easy chip. Other cutter of the blade is thickness,it will waste the material and kerf easy broken.

- Beautiful Look and Design: Our blade come with fashion design and beautiful appearance, deeply attract most of the customer and most popular on the market.

Feature:

- Good cutting result and high efficiency

- Long lifespan and stable performance

- Easy and fast cutting, no edge broken.

- Highly cost effective and premium quality

- Using high quality material and diamond

Specifications:

|

Product Name

|

Diamond Saw Blade

|

|||

|

Application

|

Construction & Civil Engineering,Stone Processing & Decoration,Manufacturing & Industrial Fields

|

|||

|

Customized support

|

OEM, ODM, OBM

|

|||

|

Size

|

80mm 100mm 110mm 150mm 200mm 250mm 300mm 350mm 400mm 450mm 500mm

|

|||

|

Bore

|

16-50mm

|

|||

|

Shape

|

Round disc

|

|||

|

Thickness

|

0.5-2mm

|

|||

|

Delivery Time

|

According to the production schedule

|

|||

|

Package

|

50pcs inner box

|

|||

Application:

- Construction & Civil Engineering

- Concrete cutting: Road surfaces, wall grooving, demolition tasks.

- Asphalt cutting: Road repair, expansion joint processing.

- Reinforced metal cutting: Steel bars in concrete structures, steel pipes.

- Stone Processing & Decoration

- Natural stone cutting: Granite, marble slab segmentation, and shaped processing.

- Tile/ceramic cutting: Precision cutting for indoor/outdoor decorative materials.

- Manufacturing & Industrial Fields

- Glass/crystal cutting: Precision machining for optical glass and semiconductor materials.

- Refractory material cutting: High-temperature materials like bricks and ceramic fiber boards.

- Specialized Applications

- Emergency rescue: Rapid concrete/metal obstacle demolition in earthquakes or accidents.

- Dry/wet cutting environments: Adaptable to no-cooling conditions (dry) or dust-reduction needs (wet).

-

Usage and Maintenance:

- Proper Installation: Securely mount the wheel on the grinding machine following the manufacturer’s instructions.

- Speed Compatibility: Operate the wheel at the recommended speed to prevent damage and ensure optimal performance.

- Regular Inspection: Inspect the wheel for wear and damage after each use, and dress or true the wheel as needed to maintain its profile.

- Storage Conditions: Store the wheels in a cool, dry place away from direct sunlight and moisture to prolong their lifespan.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, when using diamond grinding wheels.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about :

- Contact us at:

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.