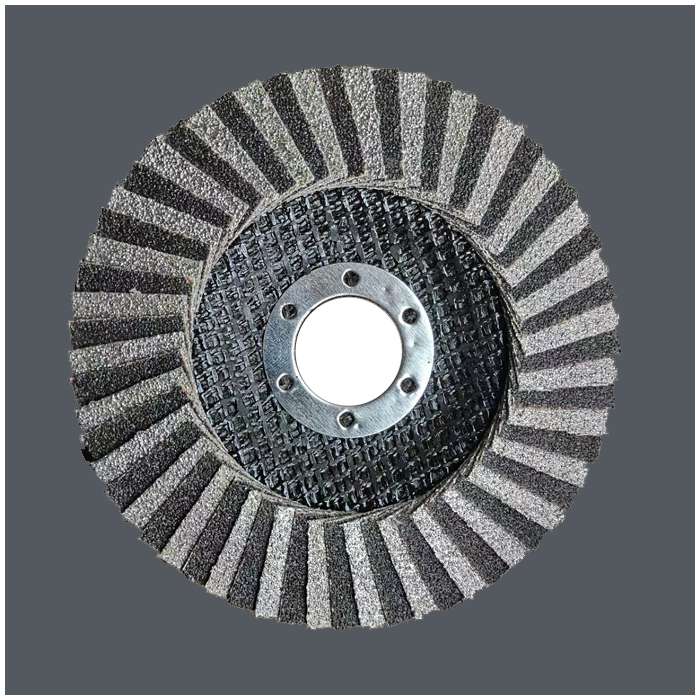

Description:

- Diamond Flap Discs are advanced abrasive tools designed for heavy-duty grinding, cutting, and polishing tasks. These discs feature diamond abrasives that offer unparalleled hardness and wear resistance, making them suitable for a wide range of materials, particularly those that are hard or difficult to machine. Diamond Flap Discs are commonly used in industries such as construction, automotive, and precision engineering.

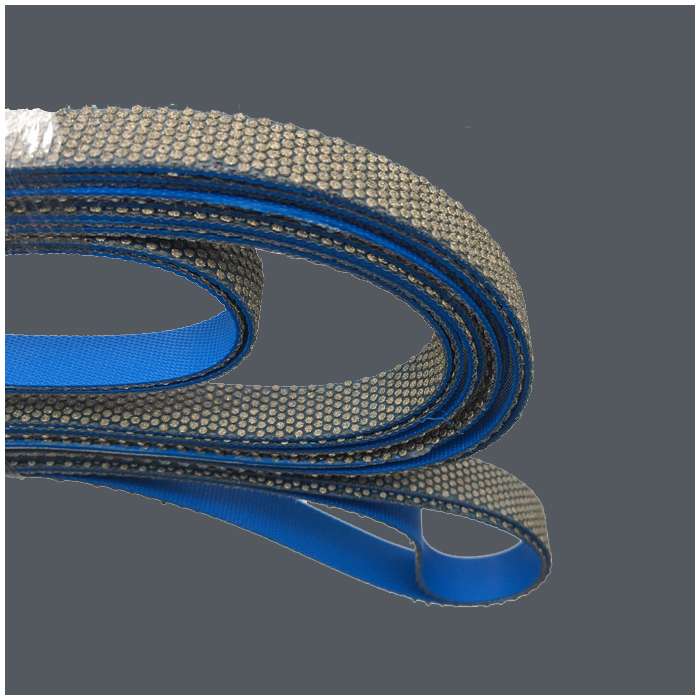

- Taking synthetic diamond as abrasive,Diamond flap disc is superhard material coated abrasive product which is manufactured under brand-new technology.It has dual advantages that are softness of conventional abrasive and hardness of diamond.Compared with conventional sand belts,the characteristics of diamond sand belt are high grinding efficiency,good wear-resistance,excellence smoothness,high cost-effective,little dust and low noise.

Feature:

- Superior Hardness: Diamond’s extreme hardness allows for efficient cutting and grinding of materials like granite, concrete, and hardened steel.

- Long-lasting Performance: The durability of diamond ensures these flap discs maintain their cutting edge for an extended period, reducing the need for frequent replacements.

- Fast Material Removal: Diamond flap discs provide rapid stock removal with minimal heat generation, which is ideal for applications where heat damage is a concern.

- Versatile Applications: They are suitable for various materials, including metals, ceramics, stone, and more, depending on the bond and grit size.

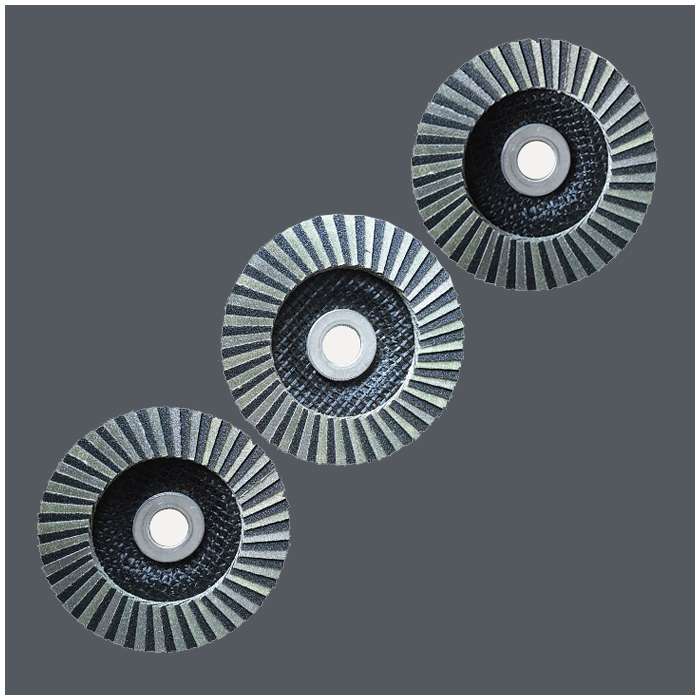

Specifications:

Diam. x Bore (mm) | Grit Available | Max. RPM | Packing ( units/pcs) |

| 100 x 16 | P40/P60/P80/P100/P120/P150/P180/P240/P320–P5000 | 15,300 | 10 |

| 115 x 22 | P40/P60/P80/P100/P120/P150/P180/P240/P320–P5000 | 13,300 | 10 |

| 125 x 22 | P40/P60/P80/P100/P120/P150/P180/P240/P320–P5000 | 12,200 | 10 |

Application:

- Construction: For grinding and polishing concrete, masonry, and stone surfaces.

- Automotive: For cutting and shaping automotive parts and accessories.

- Precision Engineering: For fine grinding and polishing of high-precision components.

- Masonry: For shaping and finishing tiles, bricks, and other masonry materials.

- Diamond flap discs are mainly used in grinding and polishing stone,glass,ceramics,mono-crystal silicon,polycrystal silicon,synthetic material,cemented carbide,alluminium alloy,etc.

Usage and Maintenance:

- Proper Installation: Securely mount the disc on the grinding machine according to the manufacturer’s guidelines.

- Speed Compatibility: Operate the disc at the speed recommended by the manufacturer to prevent damage and ensure optimal performance.

- Regular Inspection: Regularly inspect the disc for signs of wear or damage and replace it as needed to maintain cutting performance.

- Storage Conditions: Store the discs in a cool, dry place away from direct sunlight and moisture to prolong their lifespan.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and dust masks, when using diamond flap discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.