Description:

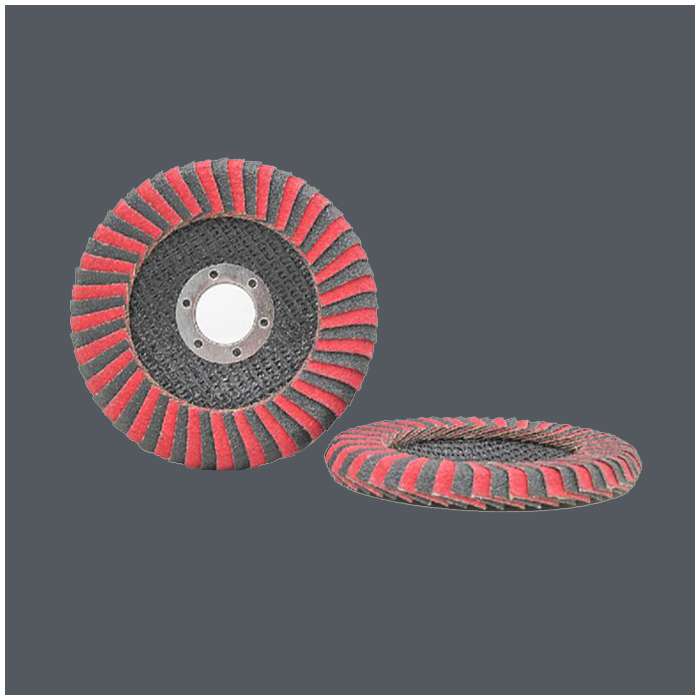

- Covered Edge Flap Discs are a type of abrasive tool designed for grinding, finishing, and polishing tasks. These discs feature a protective cover on the edge, which enhances safety and reduces the risk of accidental injury or damage to the workpiece. The covered edge provides additional support and stability during use, making them suitable for a variety of materials and applications.

- Material: Refined aluminum oxide grain /Zirconia oxide grain/Ceramic oxide grain/Ceramic plus grain

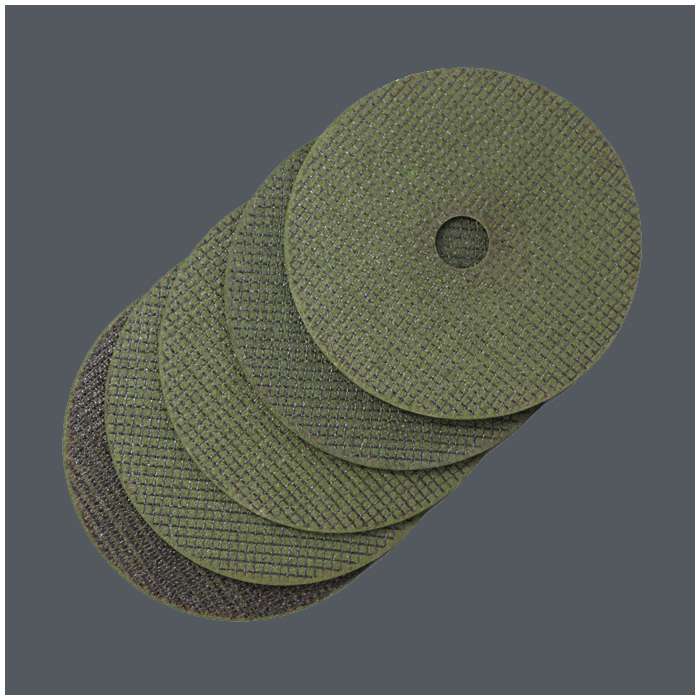

- Backing: Reinforced fiberglass backing.

- Type: Half covered /Full covered

Feature:

- Safety Edge: The covered edge offers a safer grinding experience by minimizing the exposure of abrasive material and reducing the risk of chipping or flaking.

- Enhanced Stability: The protective cover on the edge adds rigidity, ensuring a more stable and controlled grinding process.

- Versatile Application: Suitable for a wide range of materials including metals, wood, and certain plastics, depending on the type of abrasive used.

- Long-lasting Durability: High-quality abrasive materials ensure the flap discs maintain their performance over time.

Specifications:

Diam. x Bore (mm) | Grit Available | Max. RPM | Packing ( units/pcs) |

| 100 x 16 | P24/P36/P40/P60/P80/P100/P120/P150/P180/P240/P320 | 15,300 | 10 |

| 115 x 22 | P24/P36/P40/P60/P80/P100/P120/P150/P180/P240/P320 | 13,300 | 10 |

| 125 x 22 | P24/P36/P40/P60/P80/P100/P120/P150/P180/P240/P320 | 12,200 | 10 |

| 150 x 22 | P24/P36/P40/P60/P80/P100/P120/P150/P180/P240/P320 | 10,200 | 10 |

| 180 x 22 | P24/P36/P40/P60/P80/P100/P120/P150/P180/P240/P320 | 8,500 | 10 |

Product Application:

- Metalworking: For deburring, grinding, and polishing metal surfaces.

- Woodworking: For sanding and finishing wood surfaces with a smooth finish.

- Automotive: For polishing and refinishing automotive parts and bodywork.

- Construction: For grinding and smoothing concrete and masonry surfaces.

- Recommended Applications: Covered Edge Flap Discs are specially working for hard to touch, in right angle or T angel for deburring; removing welding seams and spots; removing scale, rust and oxidation of any kind.

- Work Surfaces: Alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, steel, plastic, wood etc.

Usage and Maintenance:

- Proper Installation: Ensure the disc is securely mounted on the grinding machine according to the manufacturer’s instructions.

- Speed Compatibility: Operate the disc at the recommended speed to prevent damage and ensure optimal performance.

- Regular Inspection: Inspect the disc for wear and damage after each use, and replace when necessary.

- Storage Conditions: Store in a cool, dry place away from direct sunlight to maintain the integrity of the abrasive material.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when operating flap discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.