Description:

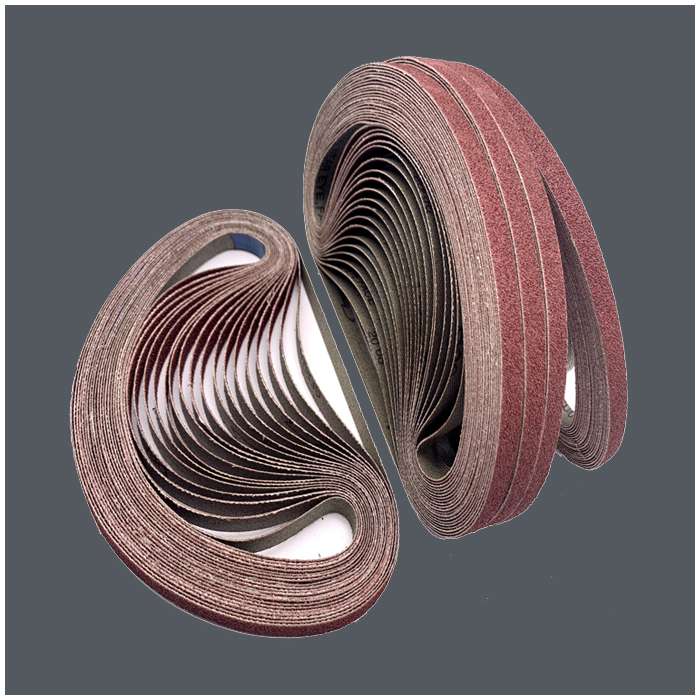

- Sanding belts, also known as abrasive belts, are widely used abrasive tools for surface grinding and polishing of materials such as metal, wood, and plastic. The abrasive surface of a sanding belt is made by bonding abrasive grains onto a flexible backing material like cloth, paper, or other materials, offering efficient and versatile grinding characteristics.

- Material: Aluminum oxide cloth, zirconia cloth, ceramic cloth,silicon Carbide.

- Joint: overlap joint and butt joint.

- Work Surfaces: Stainless steel, standard steel, alloyed steel, aluminum, nonferrous metals and alloys, cast iron.

Features:

- Efficient Grinding: Sanding belts offer high grinding efficiency, capable of quickly removing material and reducing processing time.

- Flexibility: Sanding belts can be used for hand grinding or with a belt sander, adapting to various grinding angles and shapes.

- Uniform Wear: Sanding belts wear uniformly during the grinding process, providing consistent grinding results.

- Various Grit Sizes Available: Different grit sizes are provided according to grinding needs, from coarse to fine.

Specifications:

Width x Length (mm) | Grit available | Package Units/ pcs | ||||||||

| 10 x 330 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 100 |

| 13 x 454 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 50 |

| 20 x 520 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 20 |

| 25 x 610 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 50 x 915 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 50 x 1220 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 50 x 1520 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 50 x 2745 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 75 x 2000 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 100 x 610 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 100 x 1520 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 100 x 2745 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 150 x 1220 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 150 x 1520 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 50 x 3500 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

| 150 x 2650 | P36 | P40 | P60 | P80 | P120 | P150 | P180 | P240 | P320 | 10 |

Application:

- Metalworking: Used for rust removal, deburring, smoothing, and polishing of metal surfaces.

- Woodworking Industry: Used for sanding and smoothing of wood, as well as removing paint or stains from non-wood surfaces.

- Automotive Repair: Used for the repair and refinishing of automotive surfaces.

- Recommended Applications: Grinding and cleaning, deburring, removing small protruding welded surfaces or welding spots.

- Work Surfaces: Stainless steel, standard steel, alloyed steel, aluminum, nonferrous metals and alloys, cast iron.

Usage and Maintenance:

- Proper Installation: Ensure that the sanding belt is correctly mounted on the belt sander to prevent damage due to improper installation.

- Speed Matching: Operate according to the recommended working speed of the sanding belt to ensure optimal grinding results and belt life.

- Regular Inspection: Regularly inspect the wear of the sanding belt and replace it promptly if severely worn to ensure grinding quality.

- Storage Conditions: Store away from moisture and extreme temperatures to prevent a decline in abrasive performance.

Safety Notes:

- Read the product manual and safety operating procedures carefully before use.

- Wear appropriate personal protective equipment when operating, such as safety goggles, dust masks, and gloves.

- Ensure good ventilation in the workplace to reduce the inhalation of dust and grinding particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.