Description:

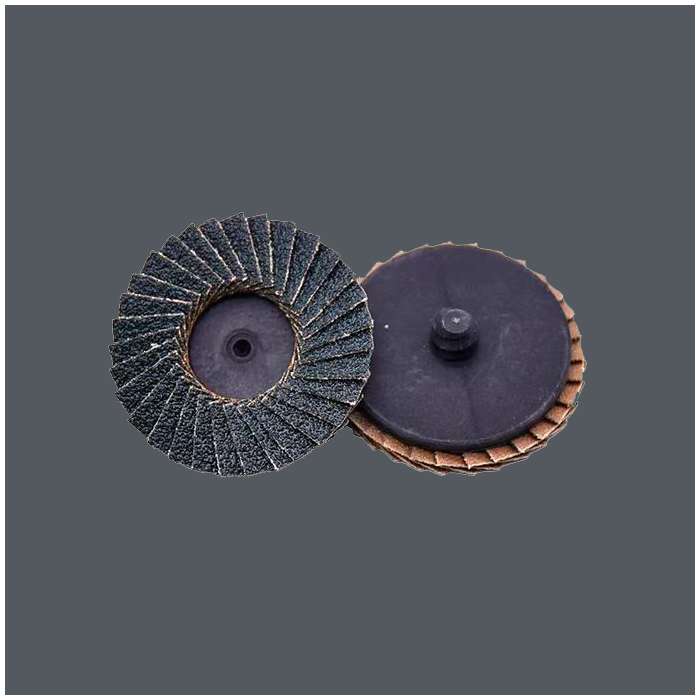

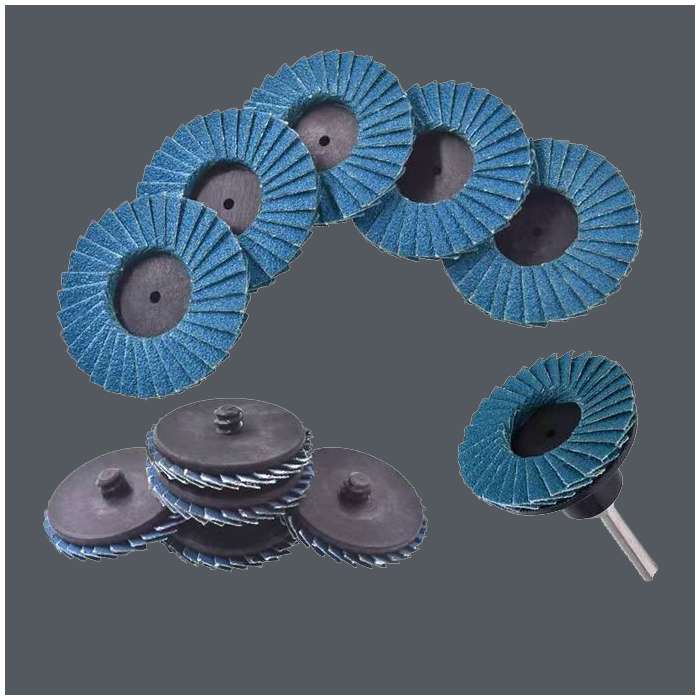

- Mini Flap Disc are compact abrasive tools designed for precision grinding, polishing, and finishing in tight spaces where larger flap discs cannot reach. These discs are ideal for detail work and are commonly used in automotive, metalworking, and hobbyist applications.

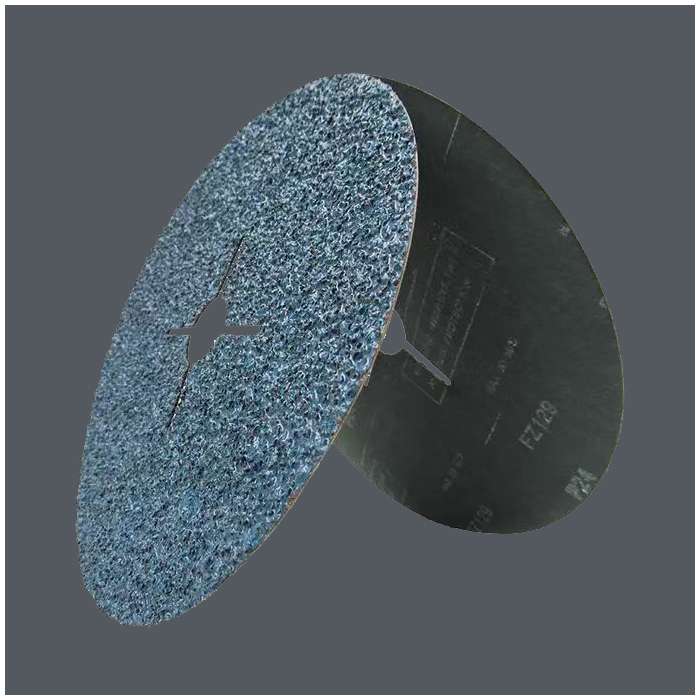

- Material: Aluminum oxide cloth/Zirconia oxide cloth/Ceramics cloth

- Backing: Plastic screw

- Type: R/S

Features:

- Compact Size: Smaller diameter and thickness allow access to confined areas and intricate details.

- Versatile Application: Suitable for a variety of materials including metal, wood, and plastic.

- Efficient Material Removal: The flap design allows for quick stock removal and even finishing.

- Long-lasting Durability: High-quality abrasive materials ensure extended disc life.

Specifications:

| Diameter | Diameter | Mounting Type | Grit Available | Max.RPM | Packing | |||||||||||||

| (mm) | (inches) | R | S | units/ pcs | ||||||||||||||

| 25 | 1 | √ | √ | P36 | P40 | P50 | P60 | P80 | P100 | P120 | P150 | P180 | P240 | P320 | 30,000 | 100 | ||

| 40 | 1.5 | √ | √ | P36 | P40 | P50 | P60 | P80 | P100 | P120 | P150 | P180 | P240 | P320 | 30,000 | 100 | ||

| 50 | 2 | √ | √ | P36 | P40 | P50 | P60 | P80 | P100 | P120 | P150 | P180 | P240 | P320 | 22,000 | 50 | ||

| 76 | 3 | √ | √ | P36 | P40 | P50 | P60 | P80 | P100 | P120 | P150 | P180 | P240 | P320 | 20,000 | 50 | ||

Application:

- Automotive Repair: For polishing and finishing small parts and areas on vehicles.

- Metalworking: For grinding and smoothing metal surfaces in hard-to-reach places.

- DIY and Crafts: For hobbyists and craft projects requiring detailed grinding and polishing.

- Recommended Applications: Mini Flap Disc is suit for Moulding and model making, manufacture and repair of cars, the aeronautical and aerospace industry.

- Work Surfaces: Stainless steel, standard steel, alloyed steel, aluminum, nonferrous metals and alloys, cast iron

Usage and Maintenance:

- Proper Fitment: Ensure the disc is securely attached to the backing pad according to the manufacturer’s instructions.

- Speed Compatibility: Operate the flap disc at the recommended speed to prevent damage and ensure optimal performance.

- Regular Inspection: Check the disc for wear and damage after each use, and replace when necessary.

- Storage Conditions: Store in a cool, dry place away from direct sunlight to maintain the integrity of the adhesive and abrasive material.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, when operating flap discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.