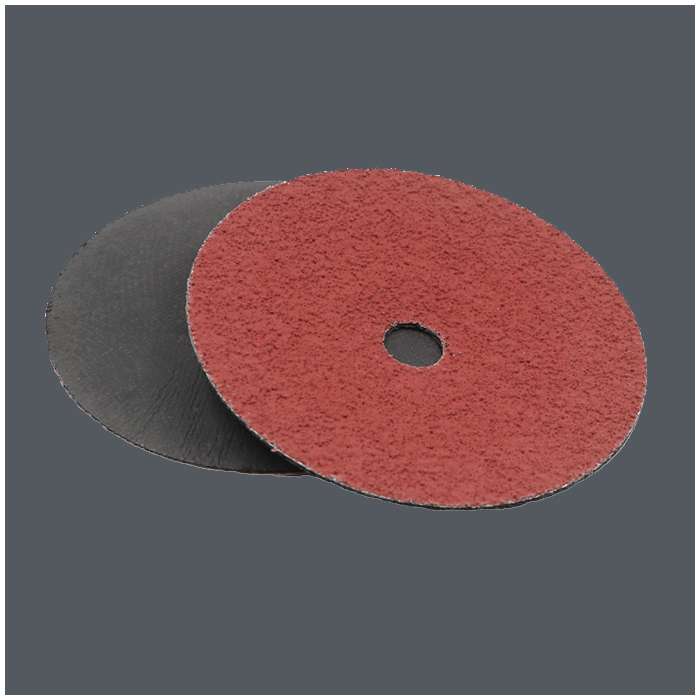

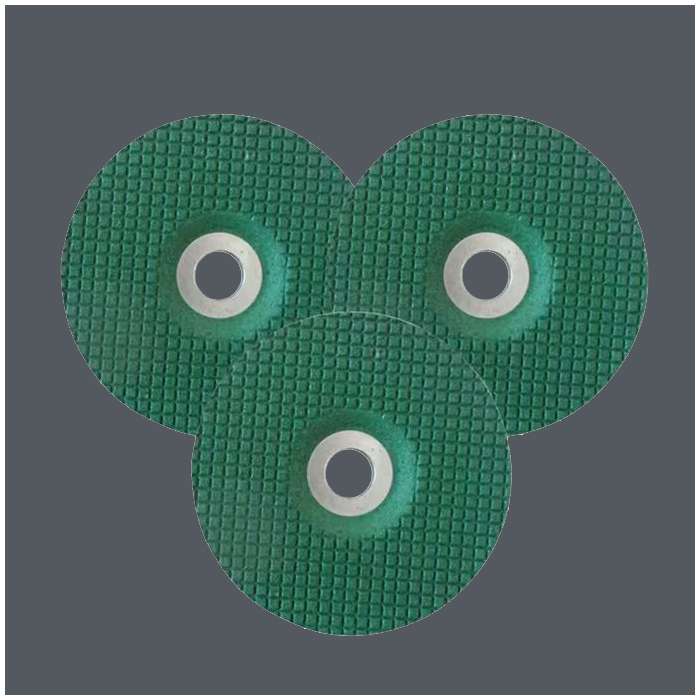

Description:

- Ceramics Fiber Discs are abrasive tools designed for heavy-duty grinding applications that demand high performance and durability. Made from a blend of ceramic aluminum oxide grains and a flexible fiber backing, these discs offer a balance of aggressive material removal and a fine finish. They are suitable for a wide range of materials, including metals, metal alloys, and certain types of hard plastics.

- Material: Premium Ceramics oxide grain with fiber backing.

- Center hole: Round /Crossing

Fearure:

- High Performance: The ceramic grains provide a sharp and durable cutting action, which is ideal for heavy grinding tasks.

- Long Lifespan: Ceramic fiber discs have a longer lifespan compared to traditional abrasives, reducing the frequency of disc changes.

- Consistent Finish: These discs deliver a consistent and even surface finish due to the uniform distribution of abrasive grains.

- Versatility: They are suitable for various grinding and finishing tasks across different industries.

Specifications:

Diam. x Bore (mm) | Grit Available | Max. RPM | Packing ( units/pcs) |

| 100 x 16 | P16/P24P36/P40/P60/P80/P100/P120 | 15,300 | 10 |

| 115 x 22 | P16/P24P36/P40/P60/P80/P100/P120 | 13,300 | 10 |

| 125 x 22 | P16/P24P36/P40/P60/P80/P100/P120 | 12,200 | 10 |

| 150 x 22 | P16/P24P36/P40/P60/P80/P100/P120 | 10,200 | 10 |

| 180 x 22 | P16/P24P36/P40/P60/P80/P100/P120 | 8,500 | 10 |

Application:

- Metalworking: For heavy stock removal and surface preparation on metals such as stainless steel, carbon steel, and aluminum.

- Automotive Industry: For deburring and finishing automotive parts.

- Construction: For grinding and leveling concrete and masonry surfaces.

- Manufacturing: For precision grinding in the production of mechanical parts.

- Recommended Applications: Ceramics Fiber Discs are suit for deburring; removing welding seams and spots; removing scale, rust and oxidation of any kind; blunting sharp corners and edges.

- Work Surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium etc.

Usage and Maintenance:

- Proper Installation: Ensure the disc is securely mounted on the grinding machine according to the manufacturer’s instructions.

- Speed Compatibility: Operate the disc at the recommended speed to prevent damage and ensure optimal performance.

- Regular Inspection: Inspect the disc for wear and damage after each use, and replace when necessary.

- Storage Conditions: Store in a cool, dry place away from direct sunlight to maintain the integrity of the abrasive material.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when operating fiber discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.