Description:

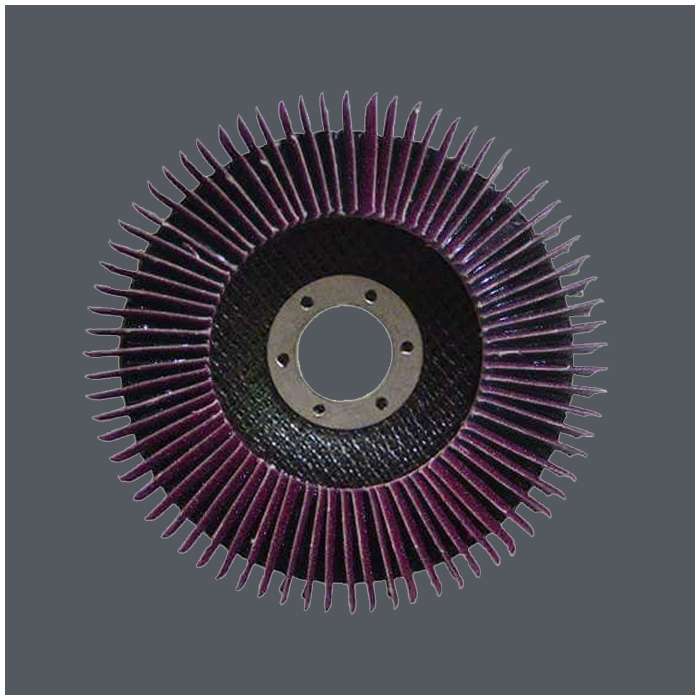

- Aluminum Oxide Flap Discs are versatile abrasive tools designed for a wide range of grinding, finishing, and polishing tasks. These discs are made with aluminum oxide grains, which are known for their hardness and ability to withstand high temperatures, making them suitable for heavy-duty applications on various materials including metals, alloys, and certain types of plastics.

- Alumina series of flap discs are manufactured by the refined aluminum oxide grains with INOX rated sulfur and chlorinated fillers that are bonded onto the flexible cotton backing cloth. All fillers are free from iron.

- Calcined Alumina oxide cloth is popular, in longer lifetime and much sharper.

Feature:

- These alumina flap discs are featured by its high stock removal even at low contact pressures, its flexibility and durability, which provides a long lasting and dynamic functionality.

- They offer an excellent grinding efficiency, a unique finish on materials with poor thermal conductivity and they can also provide significant cost savings when used with minimum contact pressure with variable-speed angle grinders at low RPM.

Specifications:

Diam X Bore(mm) | Grit Available | TYPE | Max.RPM(r/min) | Packing ( units/pcs) | |

T27 | T29 | ||||

100 X 15 | P24/36/40/60/80/100/120/150/180/240/320 |

|

| 15300 | 10 |

100 X 16 | P24/36/40/60/80/100/120/150/180/240/320 | 15300 | 10 | ||

| 115 X 22 | P24/36/40/60/80/100/120/150/180/240/320 | 13300 | 10 | ||

| 125 X 22 | P24/36/40/60/80/100/120/150/180/240/320 | 12200 | 10 | ||

150 X 22 | P24/36/40/60/80/100/120/150/180/240/320 | 10200 | 10 | ||

| 180 X 22 | P24/36/40/60/80/100/120/150/180/240/320 | 8500 | 10 | ||

230 X 22 | P24/36/40/60/80/100/120/150/180/240/320 | 6000 | 10 | ||

| 250 X 22 | P24/36/40/60/80/100/120/150/180/240/320 | 6000 | 10 | ||

Application:

- Metalworking: For deburring, grinding, and polishing metal surfaces.

- Construction: For smoothing and finishing concrete, masonry, and stonework.

- Automotive: For repair and refinishing of vehicle body parts and components.

- Manufacturing: For precision grinding in the production of various mechanical parts.

- Aluminum Oxide Flap Discs are perfect for stock removal, edge grinding, welded seams blending, deburring, de-flashing, surface finishing on various metals including carbide steel, aluminum, non-ferrous metals, plastics and wood.

Usage and Maintenance:

- Proper Installation: Ensure the disc is securely attached to the grinding machine as per the manufacturer’s guidelines.

- Speed Compatibility: Operate the flap disc at the speed recommended by the manufacturer to prevent damage and ensure optimal performance.

- Regular Inspection: Regularly inspect the disc for signs of wear or damage and replace it as needed to maintain quality and safety.

- Storage Conditions: Store the flap discs in a cool, dry place, away from direct sunlight and moisture to prolong their lifespan.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, when using flap discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust and particles.

More about :

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.