Description:

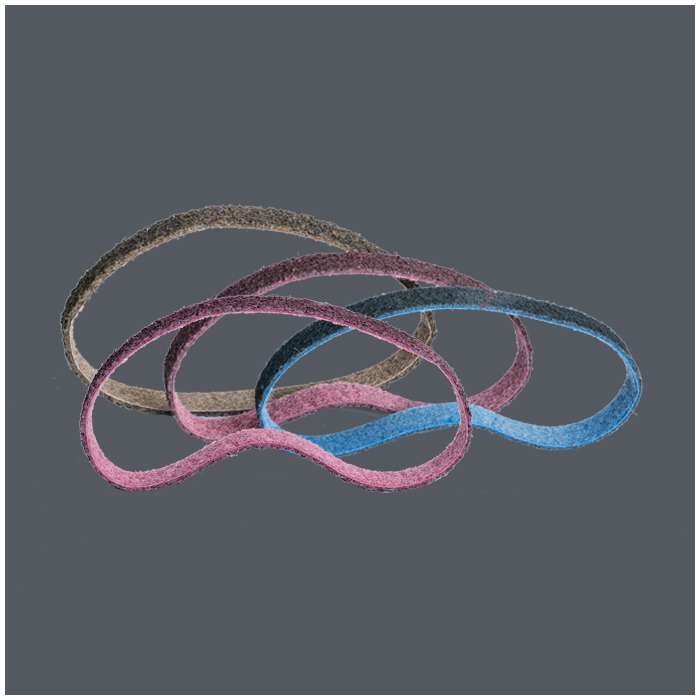

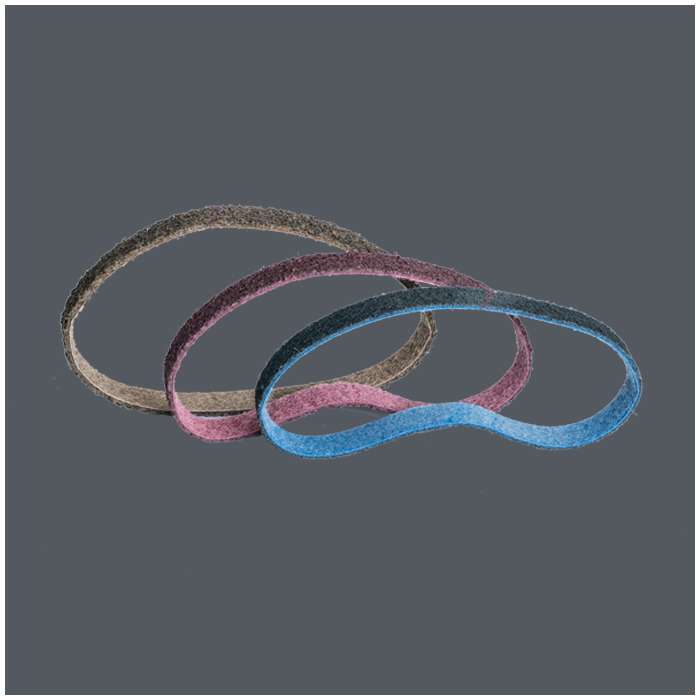

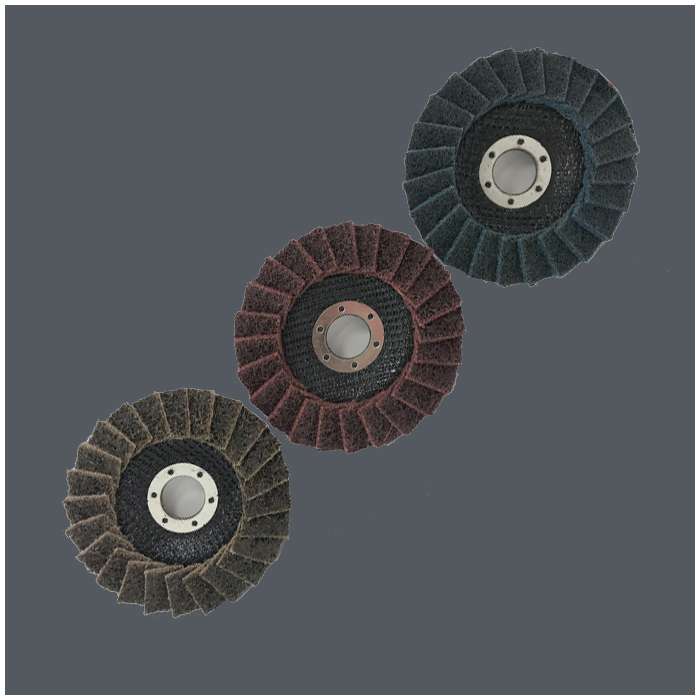

- Nylon sanding belts are converted from premium grade, resin bond coated abrasive jumbos to your specified dimensions, We only selects the best abrasive manufacturers that offer world-class technology in their products, which means our customers will benefit from the highest quality belt performance available anywhere. Belts are available in a variety of grit and grain specification for use on metal etc. Each belt can be produced in a wide range of custom size for use on many different types of equipment.

- Material: Premium surface condition materials

Feature:

- Durability: The nylon backing provides strength and resistance to wear, ensuring the belt’s longevity.

- Flexibility: The belts can conform to curved surfaces, allowing for efficient sanding in hard-to-reach areas.

- Uniform Finish: The even distribution of abrasive particles ensures a consistent and smooth finish.

- Versatility: Suitable for use on various materials, from aggressive stock removal to fine finishing.

Specifications:

Width x Length(mm) | Grits | Package Units/ pcs | ||

| 10 x 330 | Fine | Med | Coarse | 100 |

13 x 454 | Fine | Med | Coarse | 50 |

| 20 x 520 | Fine | Med | Coarse | 20 |

25 x 610 | Fine | Med | Coarse | 10 |

| 50 x 915 | Fine | Med | Coarse | 10 |

50 x 1220 | Fine | Med | Coarse | 10 |

| 50 x 1520 | Fine | Med | Coarse | 10 |

50 x 2745 | Fine | Med | Coarse | 10 |

75 x 2000 | Fine | Med | Coarse | 10 |

| 100 x 610 | Fine | Med | Coarse | 10 |

100 x 1520 | Fine | Med | Coarse | 10 |

| 100 x 2745 | Fine | Med | Coarse | 10 |

150 x 1220 | Fine | Med | Coarse | 10 |

| 150 x 1520 | Fine | Med | Coarse | 10 |

50 x 3500 | Fine | Med | Coarse | 10 |

150 x 2650 | Fine | Med | Coarse | 10 |

Application:

- Woodworking: For smoothing and preparing wooden surfaces before staining or painting.

- Metalworking: For deburring, grinding, and polishing metal surfaces.

- Plastics Processing: For shaping and finishing plastic components.

- Work Surfaces: For steel and stainless steel.

- Nylon sanding belts are available in a variety of grit and grain specification for use on metal etc. Each belt can be produced in a wide range of custom size.

Usage and Maintenance:

- Proper Installation: Attach the sanding belt securely to the sanding machine, following the manufacturer’s guidelines.

- Speed Compatibility: Operate the belt at the speed recommended by the manufacturer for optimal performance and safety.

- Regular Inspection: Inspect the belt regularly for signs of wear or damage to maintain sanding quality and prevent accidents.

- Storage Conditions: Store belts in a cool, dry place away from direct sunlight and moisture to extend their life.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when operating sanding belts.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.