Description:

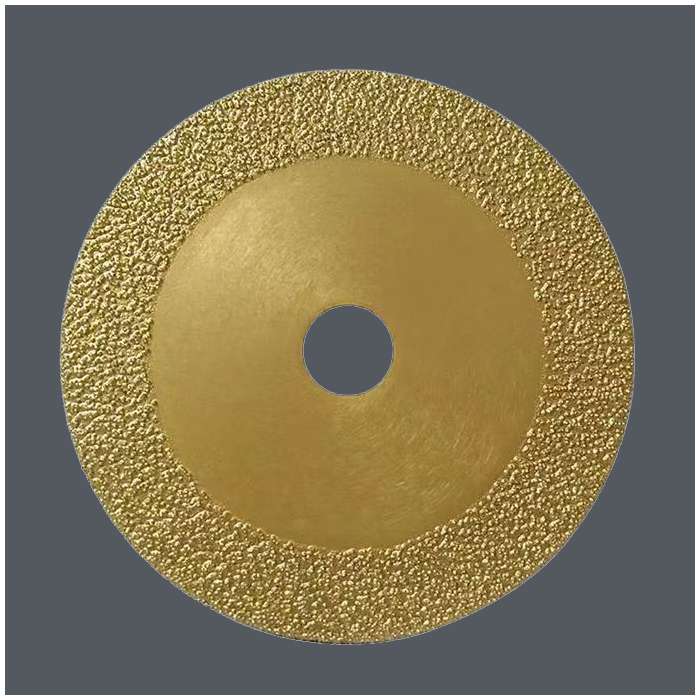

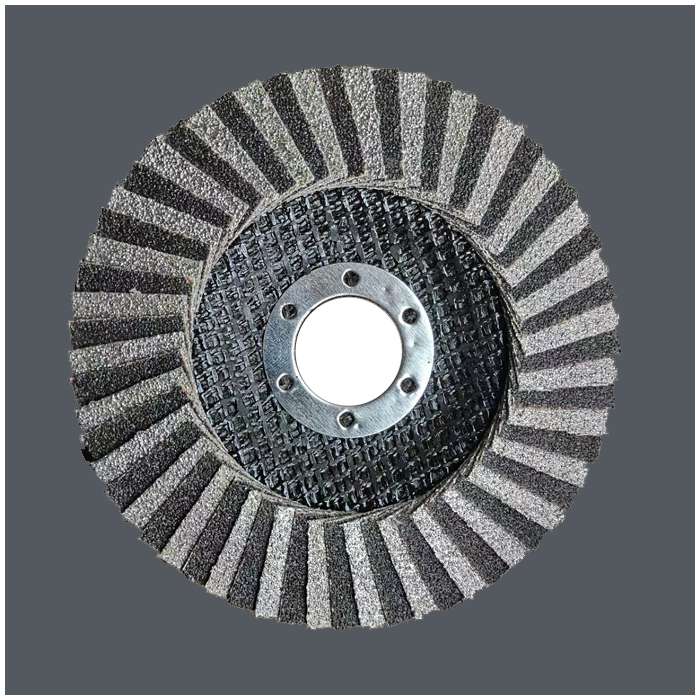

- Diamond Cutting Discs are precision cutting tools designed for applications that demand the highest level of cutting performance and longevity. These discs are embedded with diamond abrasives, which are the hardest known materials, making them ideal for cutting hard materials such as granite, concrete, ceramic, and hardened steel.

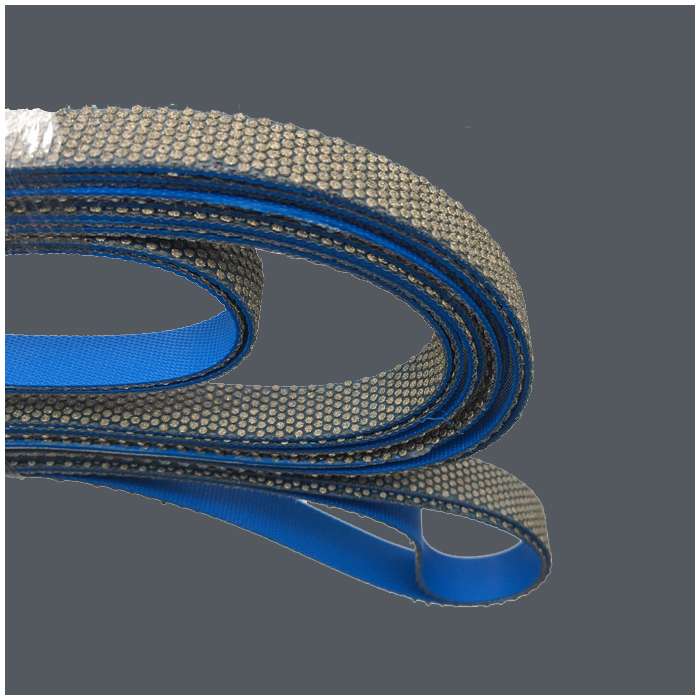

- Taking synthetic diamond as abrasive,Diamond cutting disc is superhard material coated abrasive product which is manufactured under brand-new technology.It has dual advantages that are softness of conventional abrasive and hardness of diamond.Compared with conventional sand belts,the characteristics of diamond sand belt are high grinding efficiency,good wear-resistance,excellence smoothness,high cost-effective,little dust and low noise.

Features:

- Exceptional Hardness: Diamond abrasives provide the ultimate in cutting hardness, ensuring efficient and precise cuts through the toughest materials.

- Long-lasting Durability: The superior wear resistance of diamonds means these cutting discs have an extended service life, reducing replacement frequency.

- High Cutting Speed: Diamond cutting discs offer fast cutting speeds with minimal heat generation, preserving the integrity of the workpiece.

- Versatility: Suitable for a variety of materials and applications, including construction, masonry, stonework, and metalworking.

- Large diamond segments highly increase speed of cutting and ensures smooth kerf.Feels like a lot of knife through a butter.

- Feeding should be smooth,no impact and overheating cutting,no curved cutting.

Specifications:

Diam. x Bore (mm) | Grit Available | Max. RPM | Packing ( units/pcs) |

| 16-60 | P150 | 20,000 | 10 |

| 100 x2 | P40 | 15,300 | 10 |

| 115 x 2 | P40 | 13,300 | 10 |

| 125 x 2 | P40 | 12,200 | 10 |

| 150 x 2.5 | P40 | 10,200 | 10 |

| 180 x 3 | P40 | 8,500 | 10 |

Application:

- Construction: For cutting concrete, asphalt, and other construction materials.

- Masonry: For precise cutting of bricks, tiles, and other masonry products.

- Stoneworking: For shaping and cutting natural and engineered stone.

- Metalworking: For cutting and grinding hard metals and metal alloys.

- Dianmond cutting discs are used for stone,glass,ceramics,mono-crystal silicon,polycrystal silicon,synthetic material,cemented carbide,alluminium alloy,tile,marble,granite,etc.

Usage and Maintenance:

- Proper Installation: Ensure the disc is securely mounted on the cutting machine according to the manufacturer’s guidelines.

- Speed Compatibility: Operate the disc at the speed recommended by the manufacturer to prevent damage and ensure optimal performance.

- Regular Inspection: Regularly inspect the disc for signs of wear or damage and replace it as needed to maintain cutting performance.

- Storage Conditions: Store the discs in a cool, dry place away from direct sunlight and moisture to prolong their lifespan.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and dust masks, when using diamond cutting discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.