Description:

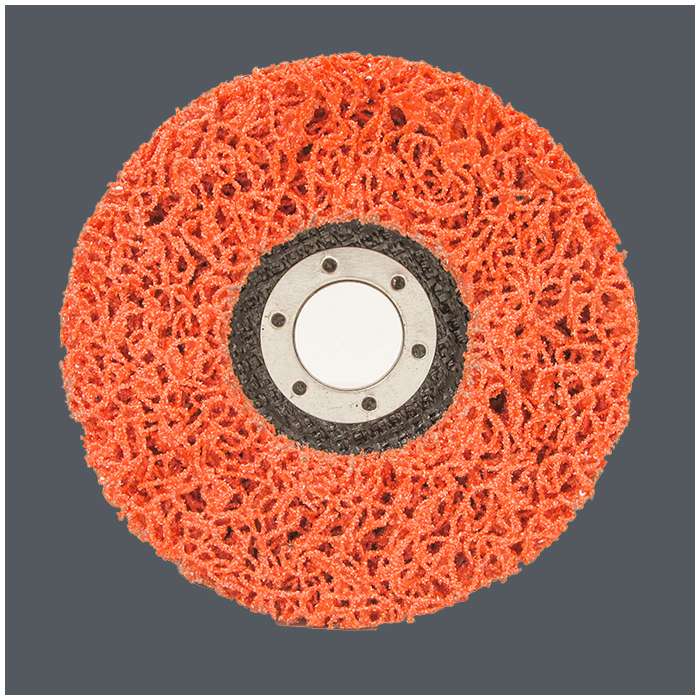

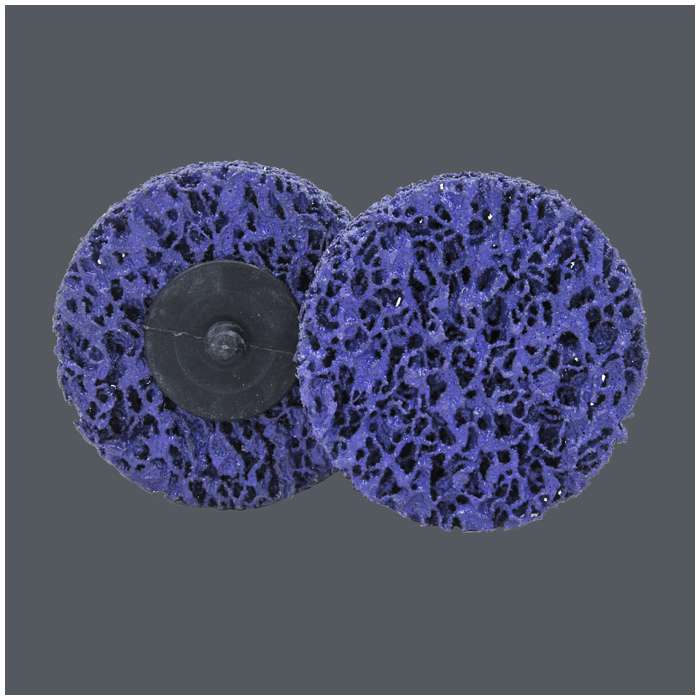

- Strip-it Flap Discs are a category of abrasives primarily used in metal manufacturing for tasks such as grinding, blending, and finishing. These discs are known for their efficiency in quick stock removal and their ability to provide a cooler cutting action with less gouging and burning compared to traditional grinding wheels.

- Material: The STRIP-IT material.

- Backing: Fiberglass backing/Nylon backing

- Color/Grit: Orange/Purple/Blue/Black

- Remarks:Black is soft,Blue & Blue will be softer, the Orange with ceramics grains is the hardest .

Feature:

- Versatility: Designed for use with right-angle grinders, these discs are suitable for a variety of tasks including heavy stock removal and surface smoothing .

- Long Lifespan: Unlike grinding wheels, flap discs continue to be effective even after the flaps wear down, offering a longer working life .

- Ease of Use: We favor them for their lightweight design, ease of control, and the reduction in vibration and noise, which enhances operator comfort and safety.

- Cost-Effectiveness: While the initial cost may be higher than some alternatives, the adaptability and robustness of flap discs make them more cost-effective in the long run .

Specifications:

| Diameter (mm) | Diameter (inches) | Color Available | Max. RPM | Packaging | |||||||||||

| Diameter x Thickness x Shaft | Diameter x Thickness x Shaft | units/ pcs | |||||||||||||

| 100 | X | 13 | X | 15 | 4 | X | 1/2 | X | 5/8 | Black | Blue | Purple | Orange | 8,000 | 5 |

| 100 | X | 13 | X | 16 | 4 | X | 1/2 | X | 5/8 | Black | Blue | Purple | Orange | 8,000 | 5 |

| 115 | X | 13 | X | 22 | 4.5 | X | 1/2 | X | 7/8 | Black | Blue | Purple | Orange | 8,600 | 5 |

| 125 | X | 13 | X | 22 | 5 | X | 1/2 | X | 7/8 | Black | Blue | Purple | Orange | 7,800 | 5 |

| 180 | X | 13 | X | 22 | 7 | X | 1/2 | X | 7/8 | Black | Blue | Purple | Orange | 5,600 | 5 |

Application:

- Metalworking: For deburring, rust removal, and surface preparation on metal components.

- Automotive: For stripping paint and preparing car body panels for repainting.

- Construction: For grinding and smoothing concrete, masonry, and other construction materials.

- Woodworking: For sanding and finishing wooden surfaces, although flap discs are more commonly used for metal and concrete applications .

- Strip-it Flap Discs can be used to rapidly removing scale and oxidation, satin finishing small surfaces, removing paints or other clogging materials such as salt, rust, grease, oil and protective waxes.

Usage and Maintenance:

- Proper Installation: Attach the flap disc securely to the power tool, ensuring it is compatible with the disc’s specifications.

- Speed Settings: Operate at the recommended speed for the task to prevent damage and ensure optimal performance.

- Regular Inspection: Check the disc for wear and damage regularly, replacing it when necessary to maintain quality and safety.

- Storage: Store flap discs in a cool, dry place away from moisture and direct sunlight to prolong their life.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask, when using flap discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.