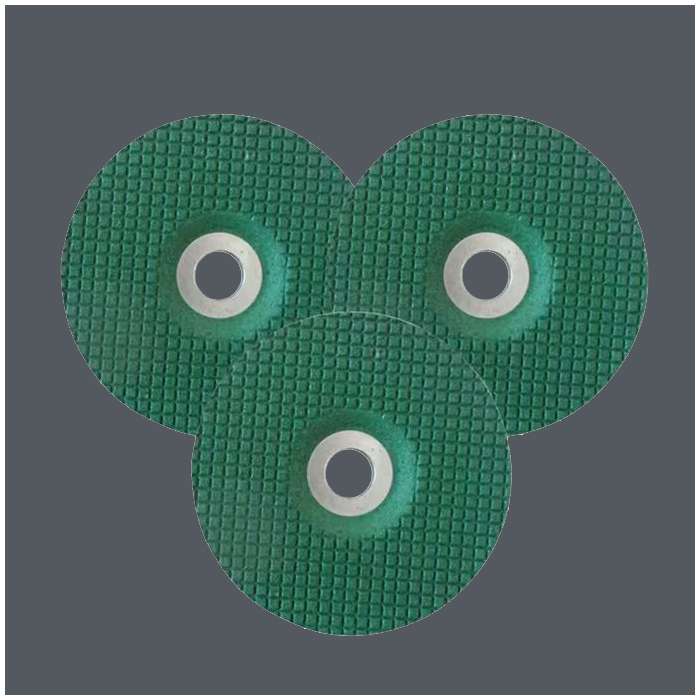

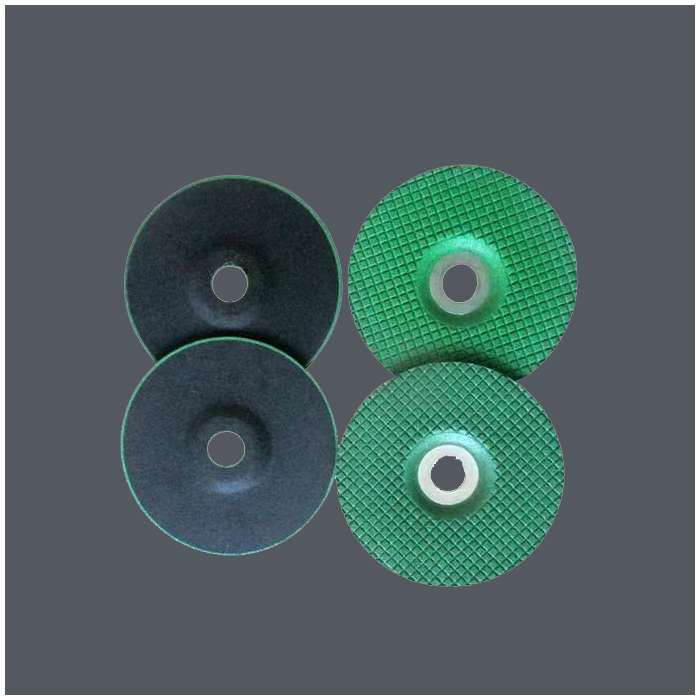

Description:

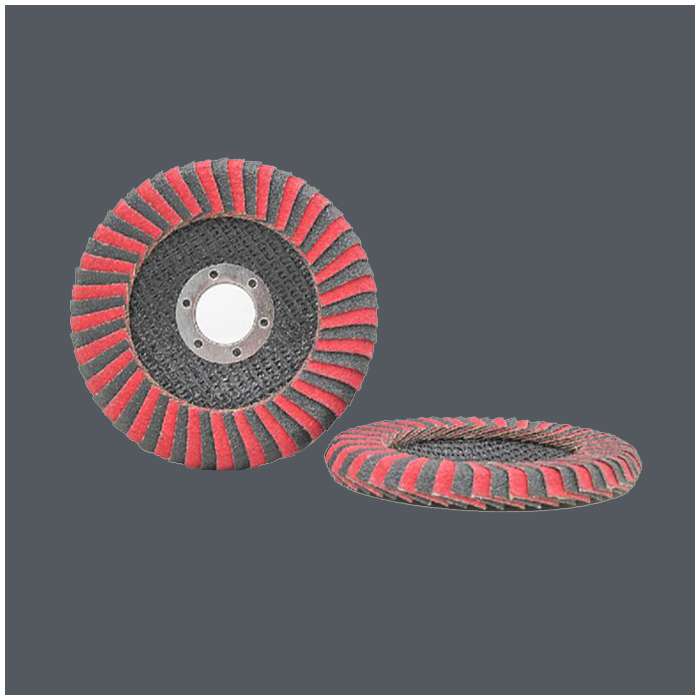

- Flexible grinding discs, often referred to as flap discs or hook and loop discs, are designed for applications that require flexibility and versatility in grinding, finishing, and polishing tasks. These discs are particularly useful for contoured surfaces and hard-to-reach areas where a more rigid grinding wheel would be less effective.

Specifications:

| SIZE | GRADE | SHAPE | MAX | PROFESSIONAL |

| RPM | PACK | |||

| 100.0 x 3.2 x 16.00 mm | A-30 | Type-27 | 15,200 | 25 |

| 115.0 x 3.2 x 22.23 mm | A-30 | Type-27 | 13,300 | 25 |

| 115.0 x 3.2 x Hub mm | A-30 | Type-27 | 13,300 | 25 |

| 125.0 x 3.2 x 22.23 mm | A-30 | Type-27 | 12,200 | 25 |

| 125.0 x 3.2 x Hub mm | A-30 | Type-27 | 12,200 | 25 |

| 150.0 x 3.2 x 22.23 mm | A-30 | Type-27 | 10,200 | 25 |

| 150.0 x 3.2 x Hub mm | A-30 | Type-27 | 10,200 | 25 |

| 178.0 x 3.2 x 22.23 mm | A-30 | Type-27 | 8,500 | 25 |

| 178.0 x 3.2 x Hub mm | A-30 | Type-27 | 8,500 | 25 |

| 230.0 x 3.2 x 22.23 mm | A-30 | Type-27 | 6,500 | 25 |

| 230.0 x 3.2 x Hub mm | A-30 | Type-27 | 6,500 | 25 |

Application:

- Metalworking: For deburring, finishing, and polishing metal components in fabrication shops and automotive repair.

- Woodworking: Used for sanding and polishing wood surfaces, removing old finishes, and preparing surfaces for staining or painting.

- Plastics and Composites: Effective for shaping and finishing plastic parts and composite materials in manufacturing processes.

Usage and Maintenance:

- Proper Fitment: Ensure the disc is securely attached to the grinding machine, following the manufacturer’s guidelines for tool speed and disc attachment.

- Speed Rating: Operate the disc within the recommended speed range to prevent damage or accidents.

- Inspection: Regularly inspect the disc for wear, damage, or glazing, and replace it as needed to maintain optimal performance.

- Storage: Store discs in a dry place, away from moisture and extreme temperatures, to prolong their lifespan.

Safety Precautions:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Use a dust extraction system when grinding to minimize exposure to airborne particles.

- Follow the manufacturer’s guidelines for disc use and machine operation to ensure safety.

- Flexible grinding discs are a valuable asset in any workshop, offering a high degree of control and adaptability for a wide range of grinding and finishing tasks. By selecting the right disc for the job, users can achieve professional results with ease.

More about the product:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.