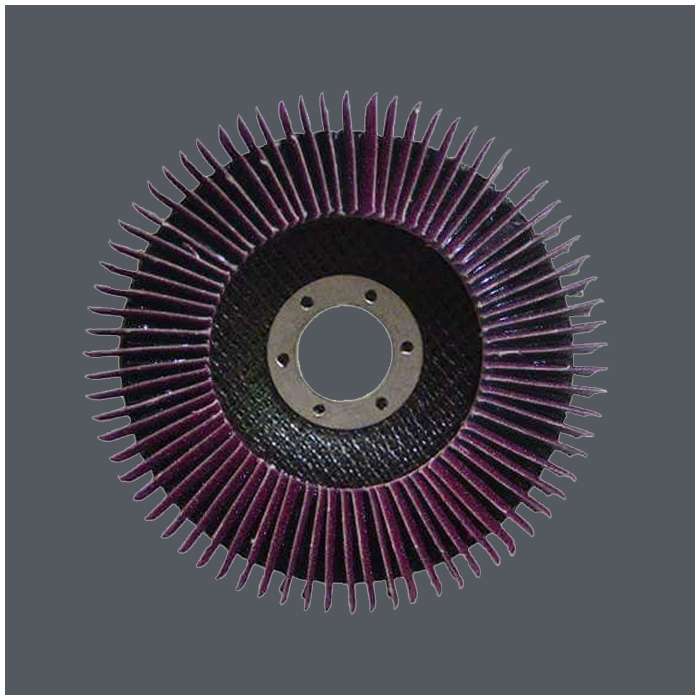

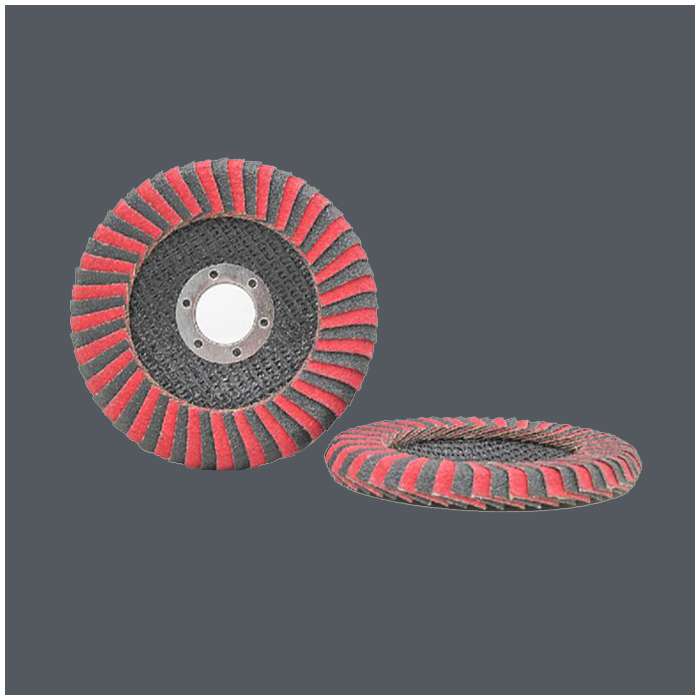

Description:

- The Vertical Flap Disc is an innovatively designed grinding tool with abrasive layers fixed perpendicular to the rotation axis, providing better stability and longer service life during grinding. Suitable for efficient grinding and polishing of various materials, especially in situations that require precise control of grinding depth.

- Material: Refined Calcined aluminum oxide grain or zirconia grain with X weight flexible cotton cloth.

- Backing: Fiberglass backing.

- Type: Vertical 90° or 60°

Features:

- High Stability: The vertical abrasive layer reduces vibration during grinding, offering a smoother and more uniform grinding effect.

- Long Life: The vertical fixation of the abrasives ensures even wear during grinding, extending the life of the flap disc.

- Efficient Grinding: The Vertical Flap Disc offers a fast material removal rate, suitable for occasions that require quick grinding.

- Various Grit Sizes Available: Different grit sizes are provided to meet various grinding requirements.

Specifications:

Diam. x Bore (mm) | Grit | Max. RPM | Packing ( units/pcs) |

| 100 x 16 | 60#/80#/120#/180# | 15,300 | 5 |

Application:

- Metalworking: Used for deburring, grinding, and polishing metal surfaces.

- Woodworking Industry: Used for sanding and surface treatment of wood products.

- Stone Processing: Used for grinding and polishing stone surfaces.

- Work Surfaces: Alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, steel, plastic, wood etc.

Usage and Maintenance:

- Proper Installation: Ensure that the flap disc is correctly mounted on the grinding equipment, following the manufacturer’s guidance.

- Speed Matching: Operate according to the recommended working speed of the flap disc to ensure optimal grinding results and disc life.

- Regular Inspection: Regularly inspect the wear of the flap disc and replace it promptly if severely worn to ensure grinding quality.

- Storage Conditions: Store away from moisture and extreme temperatures to prevent a decline in abrasive performance.

Safety Notes:

- Read the product manual and safety operating procedures carefully before use.

- Wear appropriate personal protective equipment when operating, such as safety goggles, dust masks, and gloves.

- Ensure good ventilation in the workplace to reduce the inhalation of dust and grinding particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.