Description:

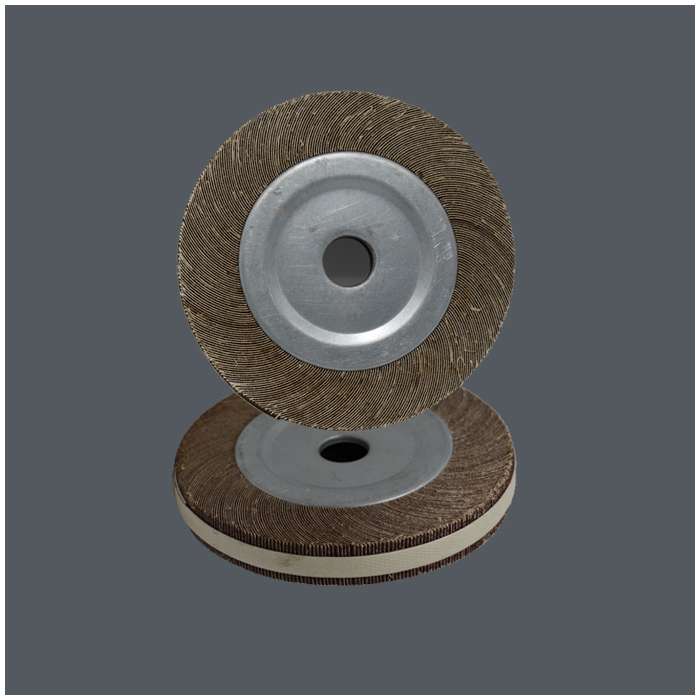

- Unmounted Flap Wheels are high-performance abrasive tools designed for surface treatment of various materials, including metals, woods, plastics, and stones.

- Unmounted Flap Wheels do not have a fixed backing plate, offering greater flexibility and adaptability, especially suitable for irregularly shaped workpieces or hard-to-reach areas.

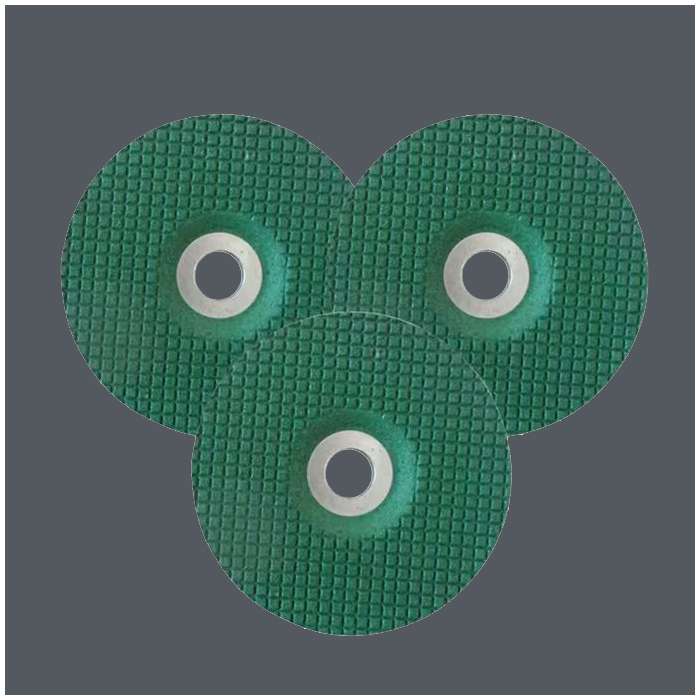

- Material: Aluminum oxide cloth, zirconia cloth or silicon oxide cloth.

- Type: Unmounted/FlangedOur unmounted flap wheel is comprised of high-quality grinding flaps coated with aluminum oxide.

- The structure of the abrasive wheel provides for very soft, comfortable grinding behavior and adapts optimally to the contours of the work piece

Features:

- Flexibility: The unmounted design allows the wheel to easily conform to various shapes and sizes of workpieces.

- Efficient Grinding: The open structure of the flap wheel aids in rapid grinding and heat dissipation, reducing the risk of thermal damage during grinding.

- Self-Sharpening: The abrasive grains naturally sharpen during the grinding process, maintaining consistent grinding results.

- Durability: High-quality abrasive materials and a robust bonding system ensure the long-lasting durability of the wheel.

Specifications:

| Dimensions (mm) | Dimensions (inches) | Grit Available | Max. RPM | Packaging | ||||||||

| Diam. x Thickness x Bore | Diam. x Thickness x Bore | units/pcs | ||||||||||

| 100 | x | 25 | x | 16 | 4 | x | 1 | x | 5/8 | P40/P60/P80/P120/P150/P180/P240/P320 | 8,800 | 10 |

| 100 | x | 50 | x | 16 | 4 | x | 2 | x | 5/8 | P40/P60/P80/P120/P150/P180/P240/P320 | 8,800 | 10 |

| 100 | x | 25 | x | 25 | 4 | x | 2 | x | 1 | P40/P60/P80/P120/P150/P180/P240/P320 | 8,800 | 10 |

| 150 | x | 25 | x | 25 | 6 | x | 1 | x | 1 | P40/P60/P80/P120/P150/P180/P240/P320 | 5,700 | 10 |

| 150 | x | 50 | x | 25 | 6. | x | 2 | x | 1 | P40/P60/P80/P120/P150/P180/P240/P320 | 5,700 | 10 |

| 165 | x | 25 | x | 25 | 6-1/2 | x | 1 | x | 1 | P40/P60/P80/P120/P150/P180/P240/P320 | 5,200 | 10 |

| 165 | x | 40 | x | 25 | 6-1/2 | x | 1-5/8 | x | 1 | P40/P60/P80/P120/P150/P180/P240/P320 | 5,200 | 10 |

| 165 | x | 50 | x | 30 | 6-1/2 | x | 2 | x | 1-3/16 | P40/P60/P80/P120/P150/P180/P240/P320 | 5,200 | 10 |

| 200 | x | 25 | x | 30 | 8 | x | 1 | x | 1-3/16 | P40/P60/P80/P120/P150/P180/P240/P320 | 4,300 | 10 |

| 200 | x | 50 | x | 54 | 8 | x | 2 | x | 2-1/8 | P40/P60/P80/P120/P150/P180/P240/P320 | 4,300 | 10 |

| 250 | x | 50 | x | 45 | 10 | x | 2 | x | 1-3/4 | P40/P60/P80/P120/P150/P180/P240/P320 | 3,400 | 10 |

| 250 | x | 25 | x | 100 | 10 | x | 1 | x | 4 | P40/P60/P80/P120/P150/P180/P240/P320 | 3,400 | 10 |

| 250 | x | 30 | x | 100 | 10 | x | 1-3/16 | x | 4 | P40/P60/P80/P120/P150/P180/P240/P320 | 3,400 | 10 |

| 250 | x | 50 | x | 100 | 10 | x | 2 | x | 4 | P40/P60/P80/P120/P150/P180/P240/P320 | 3,400 | 10 |

| 300 | x | 30 | x | 100 | 12 | x | 1-3/16 | x | 4 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,850 | 10 |

| 300 | x | 50 | x | 100 | 12 | x | 2 | x | 4 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,850 | 10 |

| 300 | x | 75 | x | 100 | 12 | x | 3 | x | 4 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,850 | 10 |

| 350 | x | 30 | x | 132 | 14 | x | 1-3/16 | x | 5-1/8 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,250 | 10 |

| 350 | x | 50 | x | 132 | 14 | x | 2 | x | 5-1/8 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,250 | 10 |

| 350 | x | 100 | x | 132 | 14 | x | 4 | x | 5-1/8 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,250 | 10 |

| 400 | x | 30 | x | 152 | 16 | x | 1-3/16 | x | 6 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,050 | 10 |

| 400 | x | 75 | x | 152 | 16 | x | 3 | x | 6 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,050 | 10 |

| 400 | x | 100 | x | 152 | 16 | x | 4 | x | 6 | P40/P60/P80/P120/P150/P180/P240/P320 | 2,050 | 10 |

Application:

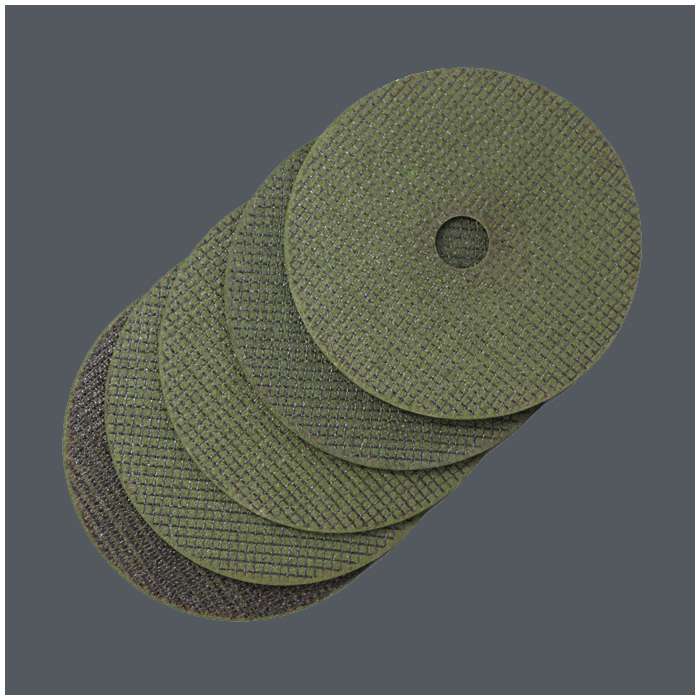

- Metalworking: For deburring, grinding, and polishing metal surfaces.

- Woodworking Industry: For sanding and surface treatment of wood.

- Automotive Repair: For the repair and refinishing of automotive parts.

- Stone Processing: For grinding and polishing stone surfaces.

- Unmounted Flap Wheels are suit for finishing wide flat, concave and convex surface, grinding the internal and outer surfaces of tanks, containers and pipers, finishing parts of irregular shape such as handles, taps and moulded parts. Removing and cleaning welding seams.

- Work Surfaces: Stainless steel, standard steel, alloyed steel, aluminum, nonferrous metals and alloys, cast iron, titanium, plastics.

Usage and Maintenance:

- Proper Installation: Ensure that the wheel is correctly mounted on the grinding equipment, following the manufacturer’s guidance.

- Speed Compatibility: Operate the flap wheel at the recommended working speed to ensure optimal grinding results and wheel life.

- Regular Inspection: Regularly inspect the wheel for wear and replace it promptly if severely worn to ensure grinding quality.

- Storage Conditions: Store away from moisture and extreme temperatures to prevent a decline in abrasive performance.

Safety Notes:

- Read the product manual and safety operating procedures carefully before use.

- Wear appropriate personal protective equipment when operating, such as safety goggles, dust masks, and gloves.

- Ensure good ventilation in the workplace to reduce the inhalation of dust and grinding particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.