Description:

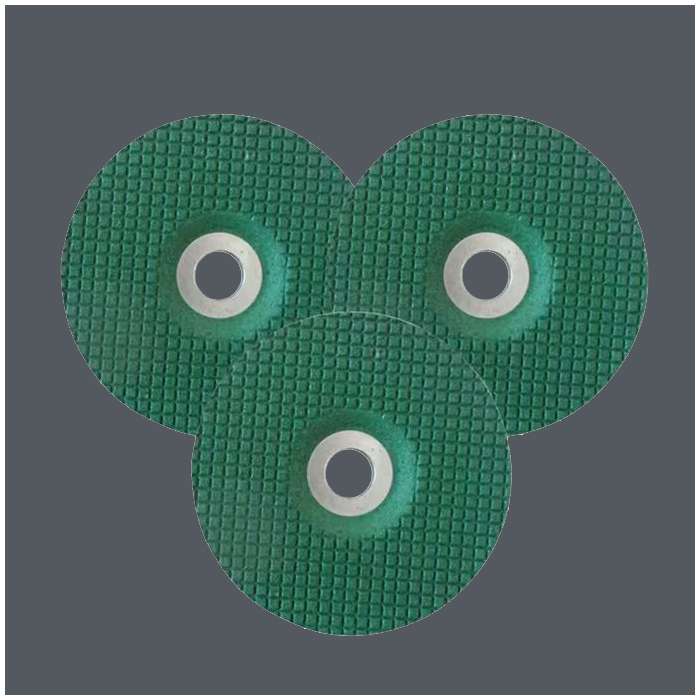

- Ceramic Alumina Flap Discs are a type of abrasive tool designed for heavy-duty grinding and finishing tasks. Made with ceramic aluminum oxide grains, these flap discs offer a combination of durability, sharpness, and fast material removal rates. They are well-suited for a variety of materials, including metals, metal alloys, and hard plastics.

- We utilize an innovative method in producing our industrial grade of Ceramic Alumina flap discs. They are constructed by using a specially designed ceramic alumina grains bonded to a flexible ply-cotton backing cloth.

- VSM Ceramics,VSM Ceramics plus

Feature:

- High Durability: The ceramic aluminum oxide grains provide a longer service life compared to traditional abrasives.

- Aggressive Cutting Action: These discs have a sharp cutting action, which is ideal for heavy grinding and quick stock removal.

- Consistent Finish: The even distribution of abrasive grains ensures a uniform and consistent surface finish.

- Versatility: Suitable for a wide range of applications, including metalworking, automotive, and general fabrication.

- The ceramic alumina grains can provide a self-sharpening action during operation.

- Ceramic Alumina flap discs can deliver an aggressive stock removal with the exceptional extended product service life. These flap discs are compatible with high powered angle grinders operated at a steep working angle for typical grinding operations.

Specifications:

Diam X Bore(mm) | Grit Available | TYPE | Max.RPM(r/min) | Packing ( units/pcs) | |

T27 | T29 | ||||

100 X 15 | P36/40/60/80/100/120 |

|

| 15300 | 10 |

| 100 X 16 | P36/40/60/80/100/120 | 15300 | 10 | ||

115 X 22 | P36/40/60/80/100/120 | 13300 | 10 | ||

| 125 X 22 | P36/40/60/80/100/120 | 12200 | 10 | ||

150 X 22 | P36/40/60/80/100/120 | 10200 | 10 | ||

| 180 X 22 | P36/40/60/80/100/120 | 8500 | 10 | ||

Application:

- Metalworking: For grinding, deburring, and polishing metal surfaces.

- Automotive Industry: For the repair and refinishing of automotive parts.

- Construction: For grinding and leveling concrete and masonry surfaces.

- Manufacturing: For precision grinding in the production of mechanical parts.

- The ceramic alumina flap discs are utilized for stock removal, edge grinding, seam weld blending, de-burring and surface finishing. They can be used on chromium steels, CrNi steels, high alloyed steel, cat iron, nickel-based alloys, titanium alloys, non-ferrous metals and even high carbide steels.

Usage and Maintenance:

- Proper Installation: Mount the disc securely on the grinding machine as per the manufacturer’s instructions.

- Speed Compatibility: Operate the disc at the recommended speed to prevent damage and ensure optimal performance.

- Regular Inspection: Inspect the disc for wear and damage after each use, and replace when necessary.

- Storage Conditions: Store in a cool, dry place away from direct sunlight to maintain the integrity of the abrasive material.

Safety Notes:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when operating flap discs.

- Ensure proper ventilation or use a dust extraction system to minimize the inhalation of dust particles.

More about:

- Contact us at:

- Skype: nancyhao0529

- What`s App: +86 136 0769 4675

- Linkedin: nancyhaoabrasives@163.com

- Facebook: nancyhao0716@gmail.com

- WeChat: nancyhao0529 / +86 136 0769 4675

- E-mail: nancy@general-abrasives.com / nancyhaoabrasives@163.com

- MobilePhone: +86 136 0769 4675

- Click the “Enquiry” button.

Reviews

There are no reviews yet.